Difference between LABSA and LAB

Introduction: Why the LAB vs. LABSA Distinction Matters

The LAB vs. LABSA debate represents a fundamental decision point in modern surfactant manufacturing. While Linear Alkyl Benzene (LAB) serves as the essential hydrocarbon precursor, Linear Alkyl Benzene Sulfonic Acid (LABSA) delivers the active cleaning power that defines end-product performance. This comprehensive analysis examines their distinct chemical properties, production pathways, and commercial applications to provide formulators, procurement specialists, and industry stakeholders with actionable intelligence for 2025 and beyond.

Understanding these differences is not merely academic; it directly impacts product performance, supply chain resilience, regulatory compliance, and bottom-line profitability in an increasingly competitive global market.

Linear Alkyl Benzene (LAB): The Strategic Hydrocarbon Foundation

Chemical Definition and Structural Properties

Advanced Production Technologies

The industrial synthesis of LAB represents a sophisticated petrochemical process centered on benzene alkylation. As of 2024, two competing technologies dominate global production capacity:

The HF (Hydrofluoric Acid) Process

This established method employs hydrofluoric acid as a catalyst for benzene alkylation with linear alpha olefins. While historically favored for its high conversion efficiency and superior product quality, HF process adoption is declining due to safety concerns and environmental scrutiny.

The Detal™ Solid Catalyst Process

UOP’s fixed-bed catalytic technology now accounts for approximately 60% of new capacity installations worldwide. The Detal™ process eliminates volatile acid handling, significantly reducing operational risks and aligning with corporate sustainability mandates. Major producers in the Middle East and Asia-Pacific have exclusively adopted this technology for recent capacity expansions.

Post-alkylation, the crude product undergoes multi-stage purification, including fractional distillation and clay treatment, to remove heavy alkylates and ensure sulfonation-grade purity exceeding 99%.

Commercial Applications and Market Dynamics

LAB’s primary value proposition is its role as a strategic intermediate. Over 90% of global LAB production converts directly into LABSA and Linear Alkylbenzene Sulfonate (LAS).

Key 2025 Market Data:

-

Global LAB demand reached 4.8 million metric tons in 2024

-

Asia-Pacific commands 52% market share, led by China and India

-

Middle East capacity expanded 18% year-over-year, with Saudi Arabia and the UAE investing heavily

-

Bio-based LAB, derived from renewable feedstocks, represents an emerging niche (<2% of total volume) but is gaining traction in premium eco-label segments.

Beyond surfactants, LAB serves as a specialty plasticizer, agricultural emulsifier component, and drilling fluid additive in upstream oil and gas operations.

Linear Alkyl Benzene Sulfonic Acid (LABSA): The Functional Surfactant Powerhouse

Chemical Structure and Performance Characteristics

Linear Alkyl Benzene Sulfonic Acid (LABSA) is the direct sulfonated derivative of LAB, with a sulfonic acid group (–SO₃H) attached to the benzene ring. This transformation fundamentally alters molecular behavior, creating a powerful anionic surfactant precursor with the general formula R-C₆H₄-SO₃H, where ‘R’ represents the linear C10-C14 alkyl chain.

The resulting amphiphilic structure—combining a lipophilic alkyl tail with a hydrophilic sulfonate head—delivers exceptional performance in reducing surface tension, emulsifying oils, and suspending particulate soils across diverse water chemistries.

Precision Sulfonation Manufacturing

The conversion of LAB to LABSA occurs through continuous sulfonation using sulfur trioxide (SO₃) gas in thin-film reactors. Modern facilities employ falling-film reactor technology for precise temperature control, typically maintaining reaction temperatures between 45-55°C to optimize product color and minimize sulfone formation.

The highly exothermic reaction demands sophisticated heat removal systems. Post-sulfonation, the crude acid undergoes hydrolysis and aging to convert residual anhydrides, producing commercial-grade LABSA with 96-97% active matter content. Leading manufacturers now implement real-time spectroscopic monitoring to ensure batch-to-batch consistency.

Primary Applications and Market Position

LABSA functions as the immediate precursor to Sodium Linear Alkylbenzene Sulfonate (LAS), the world’s most widely deployed synthetic surfactant.

2025 Consumption Breakdown by Application:

-

Household laundry detergents: 68% of global LAS consumption

-

Industrial and institutional cleaners: 15%

-

Dishwashing liquids: 12%

-

Personal care products: 5%

The molecule’s versatility extends to:

-

Heavy-duty powder detergents (asan acid slurry)

-

Liquid formulations (neutralized to LAS)

-

Industrial degreasers and emulsifiers

Recent formulation innovations focus on cold-water performance optimization and enzyme compatibility, responding to consumer demand for energy-efficient cleaning solutions.

LAB vs. LABSA: Comprehensive Technical Comparison

The following table provides a detailed, point-by-point comparison of critical parameters.

| Parameter | Linear Alkyl Benzene (LAB) | Linear Alkyl Benzene Sulfonic Acid (LABSA) |

|---|---|---|

| Chemical Nature | Hydrocarbon (alkylbenzene); neutral organic compound | Organosulfur compound; strong organic acid |

| Molecular Formula | C₆H₅-(CH₂)₁₁-₁₃CH₃ (avg. C₁₂) | R-C₆H₄-SO₃H (R = C₁₀-₁₄) |

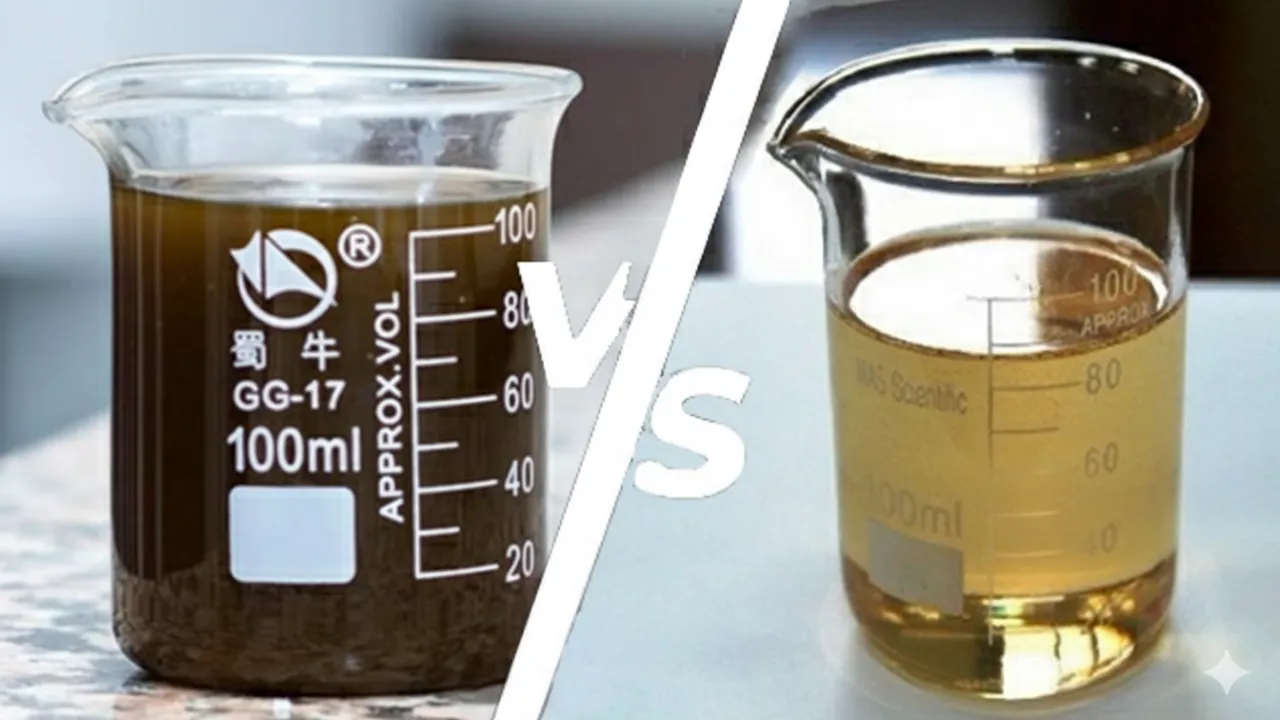

| Physical State | Colorless to pale yellow liquid; oily viscosity | Dark brown, viscous liquid (150-300 cP at 25°C) |

| Production Process | Benzene alkylation using HF or a solid catalyst | Continuous SO₃ sulfonation in falling-film reactors |

| Water Solubility | Hydrophobic; insoluble (<0.1 mg/L) | Hydrophilic; forms micellar solutions above 0.2% |

| Primary Function | Intermediate raw material; non-surface active | Surfactant precursor; active cleaning agent |

| Reactivity | Stable under ambient conditions; reactive only at alkylation temps | Highly reactive, corrosive acid; readily neutralized |

| Handling Requirements | Carbon steel tanks; standard hydrocarbon protocols | SS316, HDPE, or PTFE-lined equipment required |

| Global Capacity (2024) | 5.1 million MT/year | 4.9 million MT/year (derived) |

| Price Range (Q4 2024) | $1,450-1,650/MT (FOB) | $1,850-2,050/MT (FOB, 96% active) |

| Biodegradability | Not applicable; persistent in water | LAS derivative exceeds 98% biodegradation in 28 days (OECD 301) |

Note: Prices reflect Q4 2024 market conditions and vary by region and contract terms.

Strategic Supply Chain Implications

Integration Models: Make vs. Buy Decisions

The LAB vs. LABSA procurement strategy fundamentally shapes operational economics:

Backward Integration Model

Large multinational manufacturers (e.g., Procter & Gamble, Unilever affiliates) often purchase LAB and operate captive sulfonation units. This approach provides:

-

Direct control over LABSA quality and specifications

-

12-18% cost savings at full capacity utilization

-

Flexibility for custom alkyl chain distributions

-

Protection against LABSA supply disruptions

However, it requires $50-80 million capital investment for a 50,000 MT/year sulfonation plant, plus specialized safety and environmental management systems.

Forward Integration Model

Mid-sized and regional formulators increasingly source ready-to-use LABSA from specialized producers. Benefits include:

-

Elimination of capital expenditure

-

Access to the producer’s technical expertise

-

Reduced regulatory compliance burden

-

Just-in-time inventory management

The trade-off is margin compression, with LABSA commanding a $400-500/MT premium over raw LAB.

The 2025 Environmental and Regulatory Landscape

Regulatory frameworks continue to tighten globally. REACH Annex XVII in Europe now requires surfactants to demonstrate >95% biodegradability within 28 days. LAS, derived from LABSA, consistently achieves 98-99% degradation, securing its market position.

Moreover, carbon footprint labeling initiatives in France, Germany, and South Korea favor LABSA produced via the Detal™ process, which reduces CO₂ emissions by 0.8 MT per MT of product compared to the HF route. Forward-thinking manufacturers are now requesting Product Carbon Footprint (PCF) data from suppliers.

Emerging Market Trends Shaping Demand

Capacity Expansion

The Middle East added 620,000 MT/year of new LAB capacity in 2024, with Saudi Arabia’s Petro Rabigh and the UAE’s ENOC leading investments. Asia-Pacific will add another 850,000 MT/year by 2027, primarily in India and Indonesia.

Feedstock Volatility

Benzene prices fluctuated by 23% in 2024 due to crude oil volatility, directly impacting LAB production costs. Savvy procurement teams now hedge benzene exposure 3-6 months forward.

Performance Innovation

Research institutions are developing:

-

Low-salt LABSA grades for compact detergent formulations

-

High-active concentrates (98%+) to reduce transportation costs

-

Microbiome-friendly LAS variants for personal care applications

These innovations command 8-12% price premiums in target markets.

Conclusion: Making the Right Choice for Your Operation

The LAB vs. LABSA decision ultimately depends on your operational scale, technical capabilities, and strategic priorities. LAB offers supply chain control and cost advantages for high-volume manufacturers willing to invest in sulfonation infrastructure. Conversely, LABSA provides immediate functional performance, technical simplicity, and regulatory peace of mind for focused formulators.

With global demand projected to grow at a 4.2% CAGR through 2030, both markets present robust opportunities. However, success requires more than chemical knowledge—it demands astute supply chain management, regulatory foresight, and alignment with sustainability megatrends shaping consumer preferences.