Manufacturer and Supplier of Oxidized Polyethylene Wax (OPE Wax) from Turkey and UAE

Descriptions of Oxidized Polyethylene Wax (OPE Wax)

Oxidized Polyethylene Wax (OPE Wax) is a chemically modified polyethylene wax produced via controlled oxidation, introducing polar functional groups such as carboxyl and hydroxyl. This chemical modification enhances hardness, polarity, emulsifiability, and thermal stability, making OPE Wax an essential additive in modern manufacturing.

We are a reliable supplier of Oxidised Polyethylene Wax, offering high-quality OPE Wax suitable for diverse industries, including plastics, coatings, inks, adhesives, rubber, textiles, and leather.

Physical and Chemical Properties of Oxidized Polyethylene Wax

-

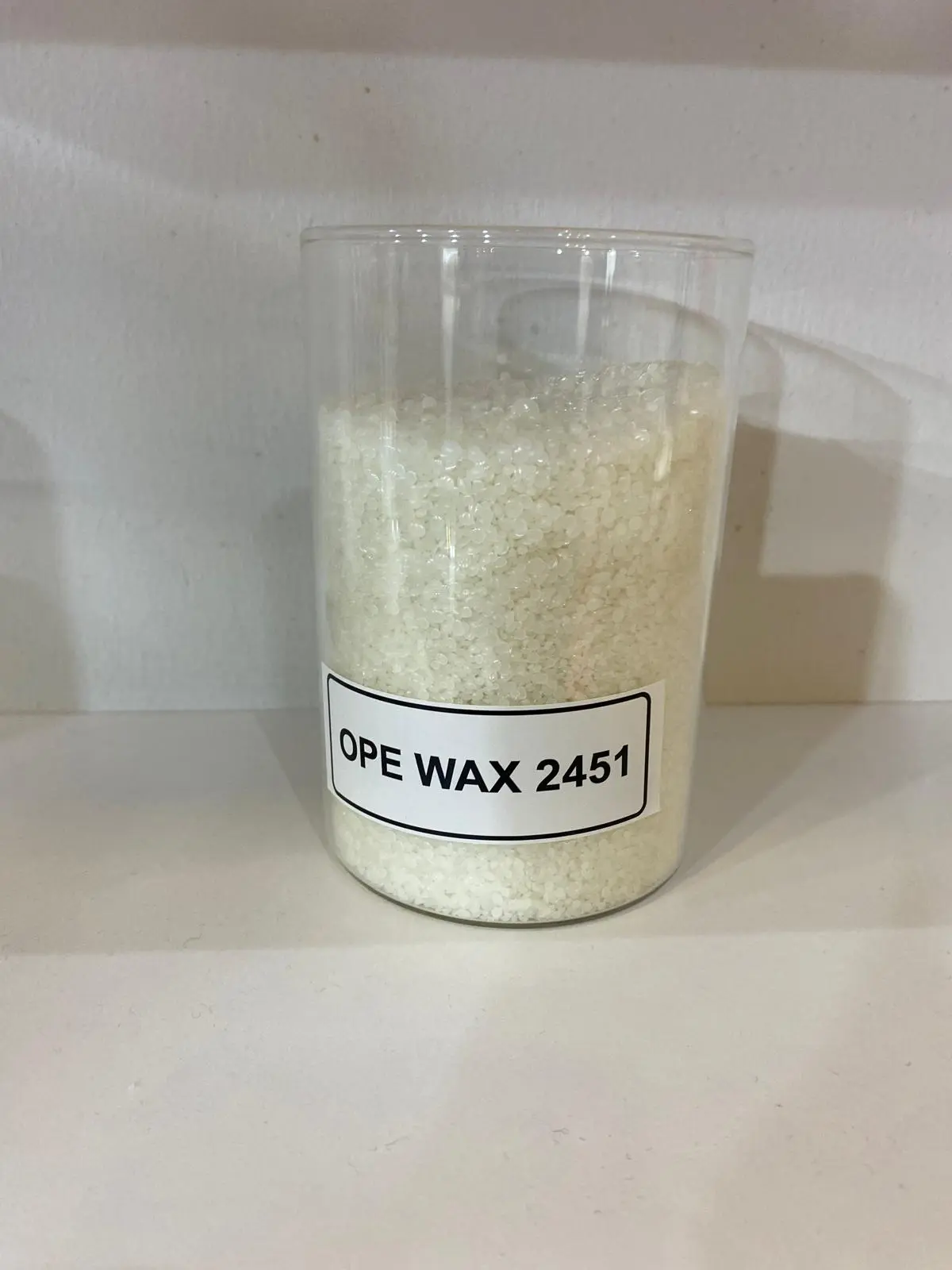

Appearance: White powder, flakes, or prills

-

Softening Point: 100 – 140°C

-

Acid Value: 10 – 30 mg KOH/g

-

Density: 0.92 – 0.99 g/cm³

-

Melt Viscosity: 200 – 10,000 cps (depending on grade)

-

Hardness: 0 – 5 dmm (25°C, penetration)

-

Particle Size: 10 – 20 µm (micronized grade)

-

Compatibility: Polar resins, PVC, adhesives, coatings

-

Stability: Resistant to acids, alkalis, and solvents

These properties allow Oxidised PE Wax to improve processing efficiency, surface quality, durability, and compatibility in multiple industrial applications.

(We can produce the above types of Wax according to the customer’s request with the acidity and viscosity they desire and deliver them to the destination ports.)

Applications Of Oxidized Polyethylene Wax (OPE Wax)

Oxidized Polyethylene Wax is a versatile industrial additive with a broad range of applications. We are supplying OPE Wax to industries where enhanced processing, surface finish, and material performance are critical.

1. Plastics and Polymer Processing

OPE Wax functions as a processing aid, lubricant, and dispersing agent in plastics and polymer manufacturing. It improves melt flow, reduces friction, and facilitates easier mold release. Its addition ensures smoother surfaces, reduced production defects, and higher efficiency in extrusion, injection molding, and compounding processes.

2. Coatings and Paints

In coatings, Oxidised PE Wax acts as a matting agent, anti-blocking additive, and surface modifier, improving scratch resistance, hardness, chemical resistance, and anti-slip properties. Its fine particle size ensures uniform dispersion, resulting in smooth, high-quality finishes in industrial paints, varnishes, and specialty coatings.

3. Inks and Printing

OPE Wax is a vital additive in inks, providing dispersing, anti-settling, and surface-enhancing properties. Even small quantities (1–3%) enhance gloss, rub resistance, and fluidity, improving print quality, drying performance, and surface uniformity in flexographic, gravure, and offset printing applications.

4. Adhesives and Sealants

In adhesives and sealants, Oxidised PE Wax adjusts viscosity, enhances tackiness, and improves bonding strength. Its polar functional groups enable better interaction with resins and other components, producing durable adhesives suitable for industrial and commercial use.

5. Rubber Industry

OPE Wax serves as a lubricant and processing aid in rubber compounding, ensuring improved mold release, reduced surface defects, and better dispersion of fillers and additives. This results in higher-quality finished rubber products, including tires, gaskets, and hoses.

6. Textiles and Leather

OPE Wax is used as a finishing agent, sizing agent, and lubricant in textiles and leather processing. It improves surface smoothness, fabric sheen, wear resistance, and durability. Additionally, OPE Wax enhances abrasion resistance and contributes to longer-lasting, high-quality fabrics and leather products.

Grades of Oxidized Polyethylene Wax

We offer multiple grades to meet different industrial needs:

-

Standard Grade – Suitable for coatings, inks, and general plastics

-

High Softening Point Grade – Ideal for rubber and high-temperature applications

-

Micronized Grade – Fine particle size for inks, coatings, and surface modifiers

-

High Acid Value Grade – Enhanced polarity for emulsions, adhesives, and specialty applications

(We can produce the above types of Wax according to the customer’s request, with the acidity and viscosity they desire, and deliver them to the destination ports.)

Packing Types Oxidized PE-Wax (OPE)

The most common packing of Oxidised PE Wax is 50 kg BOPP bags, ensuring safe transport and easy handling. Additional options include:

-

25 kg Kraft paper bags with polyethylene liner, Palletized.

-

50 kg PP bags Palletized

-

500 kg jumbo bags

-

Custom packaging available upon request

All packing options are designed to protect the wax from moisture, contamination, and mechanical damage during storage and transport.

Market Demand

The global demand for Oxidised Polyethylene Wax is growing due to its versatility and performance-enhancing properties. Industries such as plastics, coatings, inks, adhesives, rubber, textiles, and leather increasingly rely on Oxidised PE Wax to improve product quality, processing efficiency, and durability. We are committed to supplying premium-grade Oxidized Polyethylene Wax in bulk, supporting industrial and commercial production needs.

Handling, Storage, and Transportation

-

Store in a cool, dry, ventilated area

-

Keep containers tightly closed to prevent moisture absorption

-

Avoid direct sunlight and excessive heat

-

Follow standard safety procedures for handling powders and flakes

Why Choose Us as Your OPE Wax Supplier

We are a trusted supplier of Oxidized Polyethylene Wax, providing:

-

High-quality, consistent grades

-

Competitive pricing for bulk orders

-

Flexible packing and delivery solutions

-

Expert technical support for application and grade selection

We can produce the above types of Wax according to the customer’s request, with the acidity and viscosity they desire, and deliver them to the destination ports.

Contact Us

We are ready to supply Oxidised Polyethylene Wax (OPE) for your industrial applications. Contact us today to discuss your requirements, select the appropriate grade, and arrange bulk deliveries with professional guidance.

We can produce the above types of Wax according to the customer’s request, with the acidity and viscosity they desire, and deliver them to the destination ports.

Contact Information:

-

Phone/WhatsApp: +971 50 720 9246

-

Email: info@causticsodaco.com

-

Website: www.causticsoda.com

Specifications of Oxidized Polyethylene Wax (OPE)

| Product | Viscosity | Drop point | Penetration | Acid value |

|---|---|---|---|---|

| @ 140°C [mm²/s] | [°C] | [0.1 mm] | [mg KOH/g] | |

| Oxidized PE-Wax – 253 | 200 | 109 | ≤ 2 | 16 |

| Oxidized PE-Wax – 252 | 200 | 106 | ≤ 3 | 16 |

| Oxidized PE-Wax – 272 | 170 | 108 | ≤ 3 | 22 |

| Oxidized PE-Wax – 271 | 170 | 104 | ≤ 4 | 22 |

| Oxidized PE-Wax – 262 | 150 | 107 | ≤ 4 | 27 |

| Oxidized PE-Wax – 261 | 150 | 103 | ≤ 5 | 27 |

| Oxidized PE-Wax – 2628 | 50 | 105 | ≤ 6 | 27 |

Specifications of Oxidized Polyethylene Wax (OPE WAX)

Technical Data Sheet (TDS) of Oxidized Polyethylene Wax 261

| Characteristics | Reference Value | Units | Test Method |

| Acid Value | 25-29 | mg KOH/g | DGF M-IV 2 |

| Viscosity @ 140°C | 100-200 | mm2/s | DGF M-III 8 |

| Drop Point | 100-105 | °C | DGF M-III 3 |

| Solidification Point | 90-95 | °C | DGF M-III 4a |

| Needle Penetration | ≤ 5 | 10-1 mm | DGF M-III 9b |

| Density | 0.94-0.96 | g/cm3 | DIN EN ISO 1183, C |

| Molecular weight (Mn) | 1400 | g/mol | GPC |

| Saponification value | > 45 | mg KOH/g | DGF M-IV 2 |

| Type of delivery | Fine grain | – | Visual |

| Appearance | White-yellowish | – | Visual |