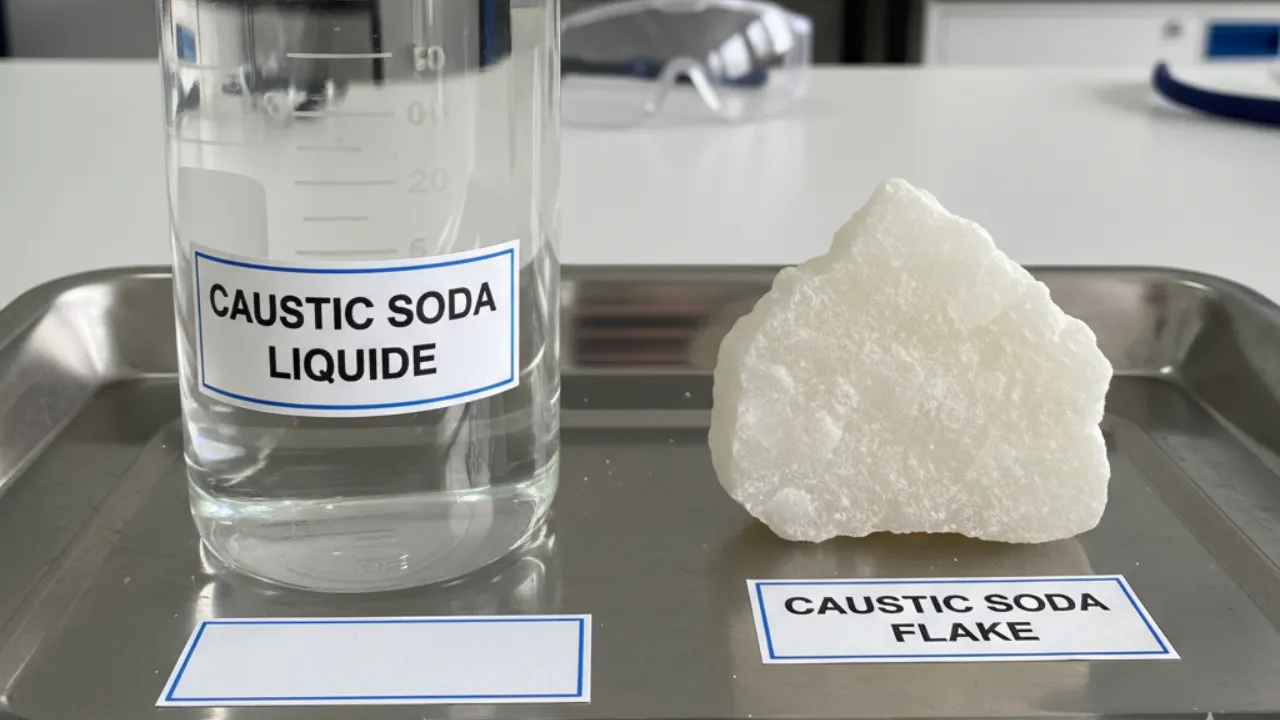

Caustic Soda Flakes vs. Liquid Caustic Soda: Ultimate 2025 Comparison Guide

Overview

In the world of industrial chemicals, the debate on caustic soda flakes vs. liquid caustic soda continues to shape manufacturing decisions. Also known as sodium hydroxide (NaOH) or lye, caustic soda is a versatile alkali essential for processes like chemical synthesis, water treatment, and food processing. As of October 2025, the global caustic soda market stands at approximately 83.2 million tons, projected to reach 95.7 million tons by 2033 with a CAGR of 1.41%, driven by sustainable applications in renewables and wastewater management. This guide refines the key differences between caustic soda flakes vs. liquid caustic soda, covering properties, uses, costs, and safety to help you choose the best form for your needs—optimized for efficiency and compliance.

Why Compare Caustic Soda Flakes vs. Liquid Caustic Soda?

Choosing between caustic soda flakes vs. liquid caustic soda boils down to your operation’s scale, process type, and safety priorities. Flakes offer high concentration for precise dosing in batch processes, while liquid forms excel in continuous flows like pH adjustment. Recent 2025 trends show flakes gaining traction in green chemistry for biodiesel, while liquid caustic soda dominates in eco-friendly water purification amid rising regulations. Understanding these nuances ensures cost savings, minimal waste, and regulatory adherence.

Physical Properties and Composition: Caustic Soda Flakes vs. Liquid Caustic Soda

The core distinction in caustic soda flakes vs. liquid caustic soda lies in their form and purity, impacting everything from storage to reactivity.

Caustic Soda Flakes

- Appearance: White, odorless, crystalline flakes—highly hygroscopic, absorbing moisture easily.

- Composition: ~99% NaOH, the most concentrated option for potent alkalinity.

- Production: Evaporated from NaOH solutions; the global flake segment is valued at ~USD 4.5 billion in 2025.

- Storage: Multi-layer bags in dry conditions to prevent clumping.

Liquid Caustic Soda

- Appearance: Clear, viscous liquid (25-50% NaOH concentration).

- Composition: Water-diluted for safer handling, retaining full caustic efficacy.

- Production: Aqueous solutions tailored to industry specs, like 50% for pulp digestion.

- Storage: Corrosion-resistant tanks to avoid leaks.

| Feature | Caustic Soda Flakes | Liquid Caustic Soda |

|---|---|---|

| Form | Solid flakes | Viscous liquid |

| Concentration | 99% NaOH | 25-50% NaOH |

| Hygroscopicity | High (absorbs moisture) | Low (pre-dissolved) |

| Shelf Life | Longer if dry | Shorter due to dilution |

This table highlights why caustic soda flakes vs. liquid caustic soda choices affect logistics—flakes ship lighter but need protection.

Solubility, Reactivity, and Handling: Key Differences in Caustic Soda Flakes vs. Liquid Caustic Soda

Handling risks vary significantly in caustic soda flakes vs. liquid caustic soda, with flakes posing higher exothermic dangers.

Caustic Soda Flakes

- Solubility: Rapid dissolution in water, releasing intense heat—perfect for quick pH spikes but prone to splattering.

- Reactivity: Ultra-reactive; requires slow addition to water to avoid boiling.

- Protocols: Full PPE (gloves, goggles, shields); OSHA PEL: 2 mg/m³. Use spill kits and training for burns.

Liquid Caustic Soda

- Solubility: Already dissolved for seamless integration—no mixing needed.

- Reactivity: Slower heat buildup, lowering injury risks.

- Protocols: Similar PPE; inspect tanks for corrosion. FDA-approved for controlled uses.

Pro tip: For high-volume ops, liquid reduces handling time by 30-50%, per 2025 efficiency studies.

Applications: Where Caustic Soda Flakes vs. Liquid Caustic Soda Shine

Industry-specific needs dictate caustic soda flakes vs. liquid caustic soda selection, with emerging 2025 uses in renewables boosting demand.

Ideal Uses for Caustic Soda Flakes

- Chemical Manufacturing: Biodiesel, soaps, and sodium hypochlorite production—high purity minimizes impurities.

- Food Processing: Olive curing, cocoa pH adjustment; FDA-grade for sanitation.

- Textiles: Scouring and bleaching for fabric enhancement.

- 2025 Trend: Cosmetics formulations for stable saponification.

Ideal Uses for Liquid Caustic Soda

- Water Treatment: pH neutralization and heavy metal removal in wastewater plants.

- Pulp & Paper: Lignin breakdown for sustainable pulp.

- Industrial Cleaning: Grease dissolution in food/beverage lines.

- 2025 Trend: Fuel cells and epoxy resins for wind energy.

| Industry | Best Form: Flakes or Liquid? | Why? |

|---|---|---|

| Chemicals | Flakes | High concentration for precision |

| Water Treatment | Liquid | Easy dosing in flows |

| Food Processing | Flakes | Pure for safety/compliance |

Economic Factors: Cost Breakdown in Caustic Soda Flakes vs. Liquid Caustic Soda

In 2025, pricing favors flakes for small batches, but liquid wins in scale—USA spot prices hover at ~USD 270/MT for both forms as of October.

Cost Efficiency

- Flakes: Higher upfront (~USD 450/MT in Q2), but less volume needed; 20-30% savings long-term.

- Liquid: Economical for continuous use; skips dissolution costs.

Transport & Storage

- Flakes: Bulk shipping savings, but moisture-proofing adds ~5-10%.

- Liquid: Pumpable but requires hazmat containers, upping freight by 15%.

Environmental and Regulatory Insights for Caustic Soda Flakes vs. Liquid Caustic Soda

Both forms demand eco-conscious handling to curb water contamination risks. EPA 2025 guidelines emphasize neutralization and recycling, with liquid forms edging out in low-spill potential.

- Impact: Mismanagement harms aquatic life; opt for closed-loop systems.

- Compliance: OSHA/EPA/FDA standards require audits; no major changes in 2025, but green certifications rise.

Final Verdict: Choosing Between Caustic Soda Flakes vs. Liquid Caustic Soda

For precision and potency, go with caustic soda flakes in batch-heavy industries like chemicals and textiles. For seamless, large-scale integration, liquid caustic soda rules in water treatment and cleaning. With market growth to USD 60.34 billion by 2030, aligning your choice optimizes costs, safety, and sustainability. Need suppliers or custom advice? Explore verified sources for your next procurement.