Supplier of Aluminum Sulfate from Turkey and Dubai-UAE

Introduction

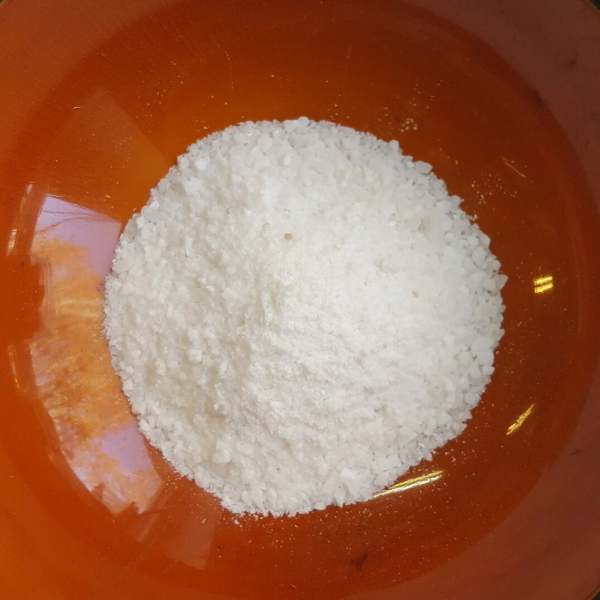

Aluminum sulfate, with the chemical formula Al₂(SO₄)₃, is a versatile inorganic compound widely used across various industries. Known for its white crystalline appearance, aluminum sulfate plays a critical role in water purification, paper manufacturing, and more. This article delves into the physical and chemical properties, grades, applications, production processes, and safety tips for handling aluminum sulfate. Whether you’re in water treatment, agriculture, or the food industry, understanding this compound can help optimize its use in your operations.

Physical and chemical properties of Aluminum Sulfate

Physical Properties

- Appearance: White crystalline solid (anhydrous) or colorless liquid (aqueous solution).

- Odor: Odorless.

- Taste: Mildly astringent and sweet.

- Density:

- 2.672 g/cm³ (anhydrous).

- 1.62 g/cm³ (octadecahydrate).

- Melting Point:

- 770 °C (1,420 °F; decomposes, anhydrous).

- 86.5 °C (187.7 °F; octadecahydrate).

- Solubility:

- Readily soluble in water (31% at 0 °C, up to 98% in boiling water).

- Slightly soluble in alcohol.

- Hygroscopic: Absorbs moisture from the air.

Chemical Properties

- Chemical Formula: Al₂(SO₄)₃.

- Molar Mass:

- 342.15 g/mol (anhydrous).

- 666.44 g/mol (octa decahydrate).

- Acidity: Forms acidic solutions due to hydrolysis.

- Non-combustible.

- Chemical Reactions:

- Decomposes upon heating (anhydrous form).

- Reacts with bases to form aluminum hydroxide precipitates.

VARIOUS GRADES of Aluminum sulfate

Aluminium sulphate is available in multiple grades, each optimized for specific industries:

- Anhydrous Aluminum Sulfate:

- Use: Preferred for water treatment and chemical synthesis due to its high concentration.

- Liquid Aluminum Sulfate:

- Use: Simplifies handling in municipal water treatment plants with rapid mixing capabilities.

- Granular Grade:

- Use: Ideal for paper manufacturing and wastewater treatment, offering quick dissolution.

- Powdered Grade:

- Use: Enhances paper sizing efficiency and textile dye fixation.

- Food-Grade:

- Use: Meets FDA standards for baking powder production and food preservation.

- Technical Grade:

- Use: Cost-effective option for industrial applications like soil stabilization.

Application and uses of Aluminum Sulfate

Aluminum sulfate is a versatile chemical compound with applications across multiple industries. Its coagulation and precipitation properties make it indispensable in many processes.

1. Water and Wastewater Treatment

- Coagulation: Neutralizes contaminants in drinking water, forming flocs for easy filtration.

- Phosphate Removal: Mitigates algal blooms in wastewater by precipitating phosphates.

- pH Adjustment: Balances alkaline water, protecting pipelines from corrosion.

2. Paper Manufacturing

- Sizing Agent: Improves ink adhesion and water resistance in paper products.

- Retention Aid: Boosts production efficiency by retaining fibers and fillers during sheet formation.

3. Agriculture and Soil Management

- Soil Acidification: Low pH for acid-loving crops like blueberries (optimal range: 5.0–5.5).

- Nutrient Delivery: Supplies sulfur and aluminum, promoting root development and crop yield.

4. Food Industry

- Pickling Agent: Maintains crispness in canned vegetables.

- Leavening Agent: Acts as a dough conditioner in commercial baking powders.

5. Textile and Leather Processing

- Mordant: Fixes dyes to fabrics, ensuring vibrant, wash-fast colors.

- Tanning: Stabilizes collagen in leather production.

6. Construction and Fire Safety

- Concrete Acceleration: Reduces setting time in cold weather concreting.

- Fire Retardant: Incorporated into foams and coatings to suppress flames.

PRODUCTION PROCESS

Aluminium sulphate is primarily produced through a chemical reaction between aluminum hydroxide and sulfuric acid.

Main Process:

- Preparation: Aluminum hydroxide (Al(OH)₃) is dissolved or suspended in water.

- Reaction: Sulfuric acid (H₂SO₄) is added under controlled conditions, yielding aluminum sulfate (Al₂(SO₄)₃).

- Chemical Equation:2Al(OH)3+3H2SO4→Al2(SO4)3+6H2O2Al(OH)3+3H2SO4→Al2(SO4)3+6H2O

- Separation and Purification:

- Filtration to remove impurities.

- Concentration through evaporation.

- Crystallization to obtain solid aluminum sulfate.

Safety Tips for Handling Aluminum Sulfate

- Wear gloves, goggles, and protective clothing.

- Work in a well-ventilated area to avoid inhaling dust.

- Wash skin immediately upon contact and remove contaminated clothing.

- Flush eyes with water for 30 minutes if splashed and seek medical attention.

- Store in a cool, dry place in labeled containers.

- Refer to safety data sheets (SDS) for specific handling and disposal guidelines.

Packaging of Aluminum Sulfate

Packaging varies based on quantity, form, and grade:

- Small Quantities: Plastic bags or resealable pouches.

- Large Quantities: Moisture-resistant bags (WPP) or bulk sacks.

- Labeling: Ensure all packages include product information, safety warnings, and handling instructions.

Conclusion

Aluminum sulfate is a multifunctional compound with applications spanning water treatment, paper manufacturing, agriculture, and more. Its unique properties and versatility make it a vital component in numerous industrial processes. By understanding its properties, grades, and applications, industries can optimize its use while adhering to safety and handling guidelines.

Read About MEG (CLICK)