Supplier of Acetic Acid From Turkey and Dubai UAE

Descriptions of Acetic Acid

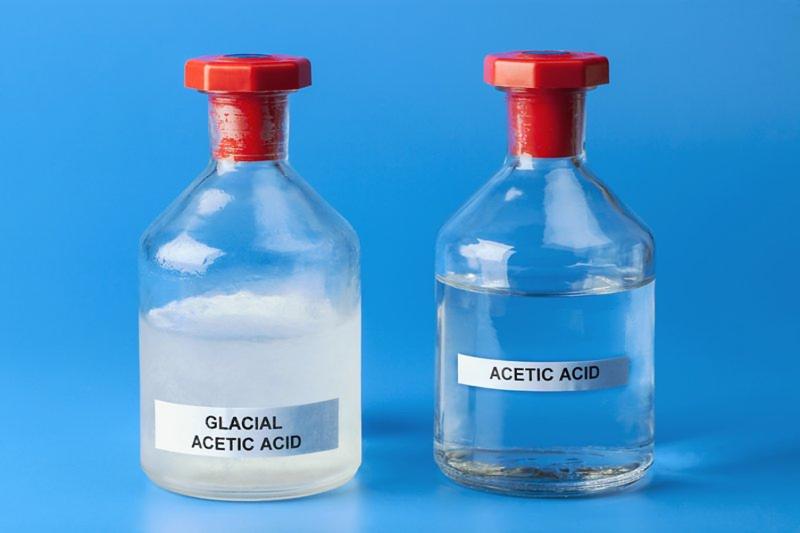

Acetic acid (also called ethanoic acid) is a widely used organic chemical with a sharp, vinegar-like odor. It is a clear, colorless liquid that plays a critical role across chemical, pharmaceutical, textile, food, and industrial sectors. Available in various grades and concentrations, it serves both high-precision laboratory applications and large-scale industrial processes.

Physical and Chemical Properties

The unique physical and chemical properties of acetic acid determine its versatility:

-

Molecular Formula: CH₃COOH

-

Molar Mass: 60.05 g/mol

-

Appearance: Colorless liquid

-

Odor: Strong, vinegar-like

-

Density: 1.049 g/cm³ at 20°C (glacial)

-

Boiling Point: 118°C

-

Melting Point: 16.6°C

-

Solubility: Completely miscible with water and polar solvents

-

Acidity (pKa): 4.76

-

Corrosiveness: Strongly corrosive to metals and living tissue

-

Reactivity: Reacts with bases, oxidizing agents, and alcohols; widely used in esterification and chemical synthesis

These properties make acetic acid highly adaptable for a wide range of industrial, chemical, and food applications.

Types and Grades of Acetic Acid

Acetic acid is produced in multiple grades to meet the requirements of different industries:

1. Glacial Acetic Acid (99–99.9%)

Glacial acetic acid is a highly concentrated, water-free form of the chemical. Its key applications include:

-

Chemical synthesis: Used as a reagent in laboratory and industrial processes

-

Textile treatment: Acts as a pH regulator and dye-fixing agent

-

Vinyl acetate monomer (VAM) production: An essential raw material in polymers and plastics

This grade is highly reactive and corrosive, suitable for precision processes requiring high purity.

2. Industrial-Grade Acetic Acid

Industrial-grade acetic acid is ideal for large-scale chemical applications where ultra-high purity is not required. Common uses include:

-

Adhesives, coatings, and plastics manufacturing

-

Rubber production and solvent synthesis

-

Intermediate chemical processes in various industrial sectors

3. Food-Grade (FCC/USP)

Food-grade acetic acid meets strict regulatory standards and is used in food processing as:

-

A preservative for pickling and packaged foods

-

An acidity regulator for beverages, sauces, and condiments

-

A flavoring agent in processed foods

This grade complies with international safety and quality standards, ensuring suitability for direct human consumption.

4. Diluted Solutions (5%–30%)

Diluted acetic acid solutions are often used in:

-

Cleaning agents and industrial descalers

-

Laboratory experiments and research applications

-

Applications requiring specific controlled concentrations

These solutions are convenient for handling and reducing risks in applications where concentrated acid is not required.

Applications of Acetic Acid

Acetic acid is a highly versatile chemical used across multiple industries:

-

Pharmaceuticals: Synthesis of intermediates and active ingredients

-

Textiles & Dyeing: Fabric treatment, pH adjustment, and dye fixation

-

Food Industry: Preservative, acidity regulator, and flavor enhancer

-

Plastics & Polymers: Production of vinyl acetate monomer (VAM) and other polymer precursors

-

Cleaning & Maintenance: Active component in industrial cleaners, descalers, and household products

-

Chemical Manufacturing: Raw material for ester, acetate, and organic compound synthesis

Its adaptability to both precision and large-scale processes makes it a fundamental chemical in modern industries.

Handling and Storage

Safe handling and storage of acetic acid are crucial due to its corrosive nature:

-

Store in ventilated, cool areas away from direct sunlight

-

Use corrosion-resistant containers such as HDPE, glass, or coated metal tanks

-

Avoid contact with oxidizers, strong bases, and reactive metals

-

Implement spill containment measures and use personal protective equipment (PPE)

Proper storage ensures stability, prevents accidents, and maintains product integrity.

Packing Options

Acetic acid is available in various packaging formats depending on application and volume needs:

-

30L & 200L HDPE drums for small and medium-scale use

-

1,000L IBC tanks for industrial-scale requirements

-

Flexitanks & ISO tanks for bulk shipment and international transport

All packaging options are designed to maintain chemical stability and allow safe handling and transport.

Technical Data Sheets Of Acetic Acid

| Property | Specification / Typical Value | Unit / Notes |

|---|---|---|

| Appearance | Clear, colorless liquid | – |

| Purity (as Acetic Acid) | ≥ 99.8% | Weight % |

| Water Content | ≤ 0.2% | Karl Fischer Method |

| Freezing Point | ≥ 16.5 °C | Confirms glacial grade |

| Boiling Point | 117.9 °C | At 1 atm |

| Melting Point | 16.6 °C | Solidifies just below room temp |

| Density @ 20°C | 1.049 g/cm³ | Typical value |

| Vapor Pressure @ 20°C | 11.4 mm Hg | – |

| Flash Point | 39 °C (closed cup) | Flammable liquid |

| pH (1% solution in water) | 2.4 – 3.0 | Acidic |

| Solubility in Water | Fully miscible | – |

| Odor | Pungent, vinegar-like | Characteristic of acetic acid |

| Grade Available | Glacial (≥99.8%), Industrial (99.5–99.7%) | Based on purity and end use |

| Packaging | Turkey / UAE / EU | Based on the supply point |