Supplier of Soda Ash (Sodium Carbonate) from Turkey and Dubai

Descriptions of Soda Ash

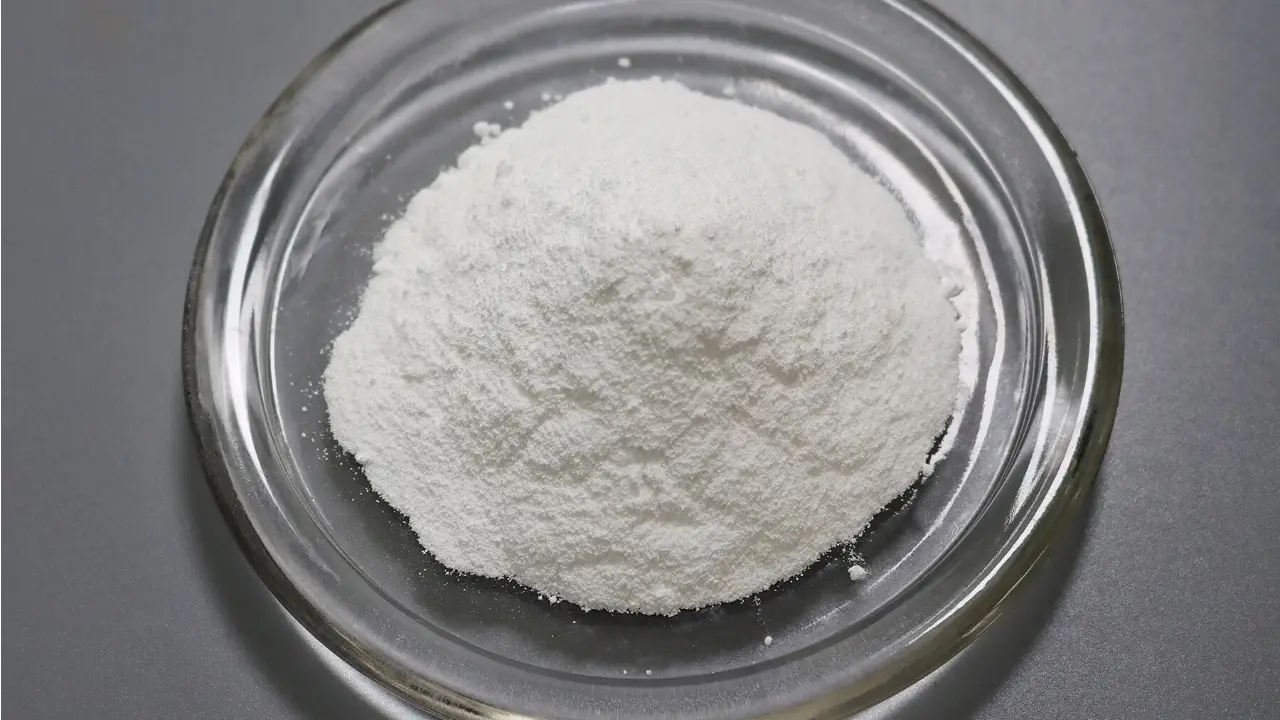

Soda ash, or sodium carbonate (Na₂CO₃), is a white, odorless, water-soluble chemical widely used in industrial and domestic applications. It produces a strongly alkaline solution in water, making it essential for glass manufacturing, detergents, chemical processes, and water treatment.

Historically, soda ash was obtained from the ashes of sodium-rich plants, but today it is produced via industrial methods or mined from natural mineral deposits, such as trona ore.

Chemical and Physical Properties of Sodium Carbonate

-

Chemical Name: Sodium Carbonate

-

Chemical Formula: Na₂CO₃

-

Molar Mass: 105.99 g/mol

-

CAS Number: 497-19-8

-

Appearance: White powder or granular solid

-

Odor: Odorless

-

Solubility: Highly soluble in water

-

pH (1% solution): Approx. 11.3–11.6

-

Melting Point: 851 °C

-

Hygroscopicity: Slightly hygroscopic

These properties make soda ash an essential compound for applications requiring alkalinity control, buffering capacity, and chemical reactivity.

Production Methods of Soda Ash (Sodium Carbonate)

1. Solvay Process (Dominant Industrial Method)

The Solvay Process remains the primary global production method. It uses:

-

Sodium chloride (NaCl)

-

Limestone (CaCO₃)

-

Ammonia (NH₃)

This method produces high-purity soda ash with lower energy consumption and reduced environmental impact compared to older technologies. Continuous process optimization has improved CO₂ recovery and waste reduction.

2. Natural Trona Ore Mining

Soda ash is also produced by refining trona ore (Na₂CO₃·NaHCO₃·2H₂O) or alkaline brines. This method is considered cost-effective and environmentally favorable, as it requires fewer chemical inputs and lower energy usage.

3. LeBlanc Process (Historical)

An obsolete method once used in Europe, replaced due to high pollution levels, high costs, and low efficiency.

Grades of Sodium Carbonate

Sodium Carbonate is commercially available in two main grades: Soda Ash Light and Soda Ash Dense. Both have the same chemical formula (Na₂CO₃) but differ in physical properties, bulk density, and applications.

1. Soda Ash Light

-

Appearance: Fine white powder

-

Bulk Density: 0.5–0.6 g/cm³

-

Solubility: Highly soluble in water, dissolves quickly

-

Primary Uses:

-

Detergent and soap production (as a builder)

-

Chemical manufacturing (sodium silicate, sodium bicarbonate, sodium tripolyphosphate)

-

Water treatment and pH adjustment

-

Textile processing for dye fixation

-

-

Advantages: Fast-dissolving, ideal for liquid formulations, cost-effective for industries needing high solubility

2. Soda Ash Dense

-

Appearance: Granular or crystalline solid

-

Bulk Density: 0.9–1.1 g/cm³

-

Solubility: Slower than light soda ash due to larger particle size

-

Primary Uses:

-

Glass manufacturing (flat glass, container glass, specialty glass)

-

Metallurgy and metal refining

-

Ceramics and enamels

-

Industrial chemicals that require solid, high-density sodium carbonate

-

-

Advantages: High bulk density, suitable for high-temperature processes and heavy-duty industrial applications

Summary of Differences:

-

Soda Ash Light: Powdery, low density, high solubility → detergents, chemical synthesis, water treatment.

-

Soda Ash Dense: Granular, high density, slower solubility → glass, ceramics, metallurgy.

Comparison Between Soda Ash Light and Soda Ash Dense

| Property | Soda Ash Light | Soda Ash Dense |

|---|---|---|

| Physical Form | Powder | Granular |

| Bulk Density | Low | High |

| Solubility | Fast | Moderate |

| Main Industries | Detergents, chemicals | Glass, ceramics |

| Handling | More dust | Less dust |

History of Sodium Carbonate

-

Ancient Civilizations: Egyptians (3500 BCE) and Romans used soda ash from plant ashes and natural deposits (natron) for glassmaking, cleaning, and mummification.

-

LeBlanc Process (18th Century): Industrialized soda ash production in Europe.

-

Solvay Process (1861): Efficient, environmentally friendly method still used today.

-

Modern Mining: Trona ore extraction remains a cost-effective source.

-

Environmental Controls: Modern production reduces emissions and waste.

Uses of Soda Ash

Industrial Uses

-

Glass Manufacturing: Lowers silica melting temperature for energy-efficient glass production.

-

Detergents and Soaps: Acts as a builder, softens water, and enhances cleaning.

-

Water Treatment: Adjusts pH in municipal and industrial systems.

-

Pulp and Paper Industry: Pulping and bleaching processes.

-

Chemical Manufacturing: Produces sodium bicarbonate, sodium silicate, and other sodium-based chemicals.

-

Textile Processing: Dye fixation and pH control.

-

Metal Refining: Extracts copper, zinc, and lead from ores.

-

Food Industry: Food additive (E500), leavening agent.

Domestic Uses

-

Cleaning agent for grease, oil, and stains

-

pH adjustment in pools and aquariums

-

Occasional baking use

Environmental Uses

-

Flue gas desulfurization

-

Soil neutralization and remediation

Specialty Applications

-

Oil and gas drilling fluids

-

Ceramics and enamel glazes

Packaging and Container Loading

-

Standard Packaging Options

-

50 kg PE / PP bags

-

1000 kg Jumbo Bags (Soda Ash Light)

-

1250 kg Jumbo Bags (Soda Ash Dense)

Container Loading Capacity

20 ft Container

-

Soda Ash Light: 16–17.2 MT

-

Soda Ash Dense: up to 26 MT

40 ft Container

-

Soda Ash Light: up to 25 MT

-

Soda Ash Dense: up to 26.25 MT

Proper palletization and moisture protection are essential during transport.

-

Safety of Soda Ash

Health Hazards

-

Skin irritation, dryness

-

Eye irritation

-

Respiratory tract irritation from dust

-

Gastrointestinal irritation if ingested in large quantities

Safety Measures

-

Wear gloves, goggles, respirators, and protective clothing

-

Store in cool, dry, ventilated areas

-

Clean spills carefully to avoid dust

-

Follow proper first aid procedures in case of contact or inhalation

Environmental Safety

-

Not highly toxic, but large releases can alter water pH

-

Avoid dumping into water bodies or soil

Specification of Soda Ash (Light)

SPECIFICATION OF SODA ASH (LIGHT)

Specification of Soda Ash (Dense)