Supplier of Caustic Soda Pearls From Turkey & UAE

Caustic Soda Pearls (NaOH) Descriptions

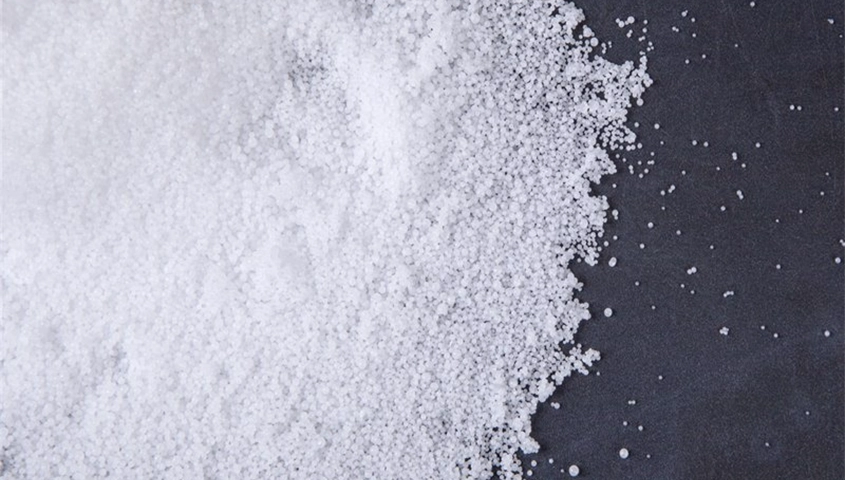

Caustic Soda Pearls, also known as Sodium Hydroxide Pearls (NaOH), are solid white, free-flowing granules with strong alkaline characteristics. They are widely used in chemical manufacturing, water treatment, oil refining, detergent production, and textile processing.

With a pH range of 12–14, caustic soda pearls dissolve quickly in water, releasing significant heat through an exothermic reaction. Their uniform spherical shape ensures high purity, minimal dusting, and easy handling, making them ideal for precise industrial operations compared to flakes or liquid caustic soda.

Physical and Chemical Properties of Sodium Hydroxide Pearls

A clear understanding of caustic soda pearls’ properties is vital for safe handling and effective industrial use:

Chemical Formula: NaOH

Molar Mass: 40.00 g/mol

Appearance: White, round, free-flowing pearls

Odor: Odorless

Density: 2.13 g/cm³ (solid)

Melting Point: 318°C

Boiling Point: Decomposes before boiling

Solubility: Highly soluble in water (up to 1,000 g/L at 20°C); releases heat upon dissolution

Alkalinity (pH): 12–14

Reactivity: Reacts strongly with acids, certain metals (such as aluminum or zinc), and moisture; produces exothermic reactions when in contact with water.

Corrosiveness: Highly corrosive to skin, metals, and organic materials

These properties make sodium hydroxide pearls a powerful and versatile alkali essential for neutralization, pH control, and chemical synthesis across various industries.

Production of Caustic Soda Pearls

Caustic soda pearls are produced through the chlor-alkali process, ensuring high purity and consistent particle quality, which is suitable for industrial applications.

-

Electrolysis of Brine: Concentrated sodium chloride (NaCl) solution undergoes electrolysis, producing sodium hydroxide, chlorine, and hydrogen gas.

-

Purification: The sodium hydroxide solution is filtered to remove impurities and unwanted residues.

-

Concentration: The purified NaOH is evaporated to increase concentration and purity levels.

-

Pearl Formation: Through controlled cooling and granulation, the concentrated liquid NaOH is solidified into uniform spherical pearls.

-

Drying and Packaging: The final product is dried, screened, and packed in moisture-resistant bags to ensure chemical stability and safety during transport.

This advanced process produces high-quality sodium hydroxide pearls with consistent chemical composition for global industrial use.

Applications of Caustic Soda Pearls

Caustic soda pearls are one of the most widely used alkaline chemicals in industrial production. Their high purity, strong reactivity, and ease of handling make them essential for numerous applications, including:

-

Soap and Detergent Manufacturing: Used for saponification of fats and oils to produce soaps and liquid detergents.

-

Textile Industry: Employed in cotton mercerization, dyeing, and bleaching processes to improve fabric strength and dye uptake.

-

Paper and Pulp Industry: Helps dissolve lignin during pulping, producing brighter and stronger paper.

-

Petrochemical and Oil Refining: Neutralizes acidic compounds and assists in desulfurization and refining of petroleum.

-

Water Treatment: Adjusts pH, removes heavy metals, and aids in wastewater neutralization.

-

Food Industry (Food-grade NaOH): Used for peeling fruits and vegetables, processing cocoa, and curing olives.

-

Aluminum and Metallurgy: Dissolves bauxite in the Bayer process for alumina extraction.

-

Pharmaceutical and Healthcare: Serves in drug formulation, cleaning, and disinfection of medical equipment.

-

Biodiesel Production: Acts as a catalyst in the transesterification process of oils and fats.

Due to its wide range of industrial applications, Sodium Hydroxide pearls are a fundamental raw material in both the chemical and manufacturing sectors.

Handling, Storage, and Transportation of Caustic Soda Pearls

Due to their corrosive and hygroscopic nature, caustic soda pearls require strict handling and storage procedures:

-

Store in airtight, moisture-proof containers in a cool, dry, and ventilated area.

-

Avoid contact with acids, metals, and moisture, which can cause dangerous exothermic reactions.

-

Always wear personal protective equipment (PPE) such as gloves, goggles, face shields, and protective clothing.

-

In case of contact, rinse immediately with plenty of water and seek medical attention.

-

During transport, follow IMCO Class 8 – Corrosive Substances guidelines, with UN number 1823, ensuring proper labeling and secure packaging.

Safe handling procedures are essential to maintain product quality and protect personnel from hazardous exposure.

Caustic Soda Pearls Packaging

Caustic soda pearls are commonly packed in 25 kg laminated polypropylene (PP) bags lined with polyethylene to protect against moisture. For bulk deliveries, they are available in 1,250 kg jumbo bags or palletized packaging, ensuring stability and ease of transport.

Container Loading Capacity

A standard 20 ft. container holds approximately 25 metric tons of NaOH pearls, providing cost-effective and secure shipping for international distribution.

Specification of Caustic Soda Pearls

| Property | Value | Unit |

|---|---|---|

| Melting Point: | 320-325 | ºC |

| Boiling Point: | 1385-1390 | ºC |

| Densityat20ºC: | 2.13 | g/cm3 |

| SolutionRate:(100g in 100ml water at25ºC): | 22 | s |

| Heat Capacity at 25ºC: | 2.01 | J/g.K |

| Heat of Fusion at 15ºC: | 167.5 | J/g |

| Standard Heat of Formation at 25ºC: | 10.67 | kJ/g |

| Specifications | ||

| Item | Value | Unit |

| Purity: | 99.0 Min | % |

| Sodium Carbonate (Na2CO3): | 0.8 Max | % |

| Sodium Chloride (NaCl): | 0.05 Max | % |

| Fe2O3: | 50 Max | PPM |