Supplier of Phthalic Anhydride

Introduction

Phthalic anhydride (C₈H₄O₃) is a cornerstone of industrial chemistry, valued for its versatility in producing plasticizers, resins, dyes, pharmaceuticals, and agricultural chemicals. As a reliable supplier of phthalic anhydride, high-purity products are delivered to meet global industry demands. Derived from ortho-xylene or naphthalene, phthalic anhydride drives innovation across multiple sectors, while safe handling protocols are essential for industrial and laboratory environments. This guide explores its properties, production methods, industrial applications, and safety considerations.

What is Phthalic Anhydride?

Phthalic anhydride is a cyclic anhydride formed by dehydrating phthalic acid. Its molecular formula, C₈H₄O₃, allows diverse chemical reactions, making it a critical raw material. Produced via catalytic oxidation of ortho-xylene or naphthalene, phthalic anhydride is essential for synthesizing plasticizers, resins, and specialty chemicals. A reputable phthalic anhydride supplier ensures high purity, reliable supply, and tailored solutions for industrial applications worldwide.

Key Properties of Phthalic Anhydride

Understanding the chemical and physical characteristics of phthalic anhydride is vital for effective industrial use:

-

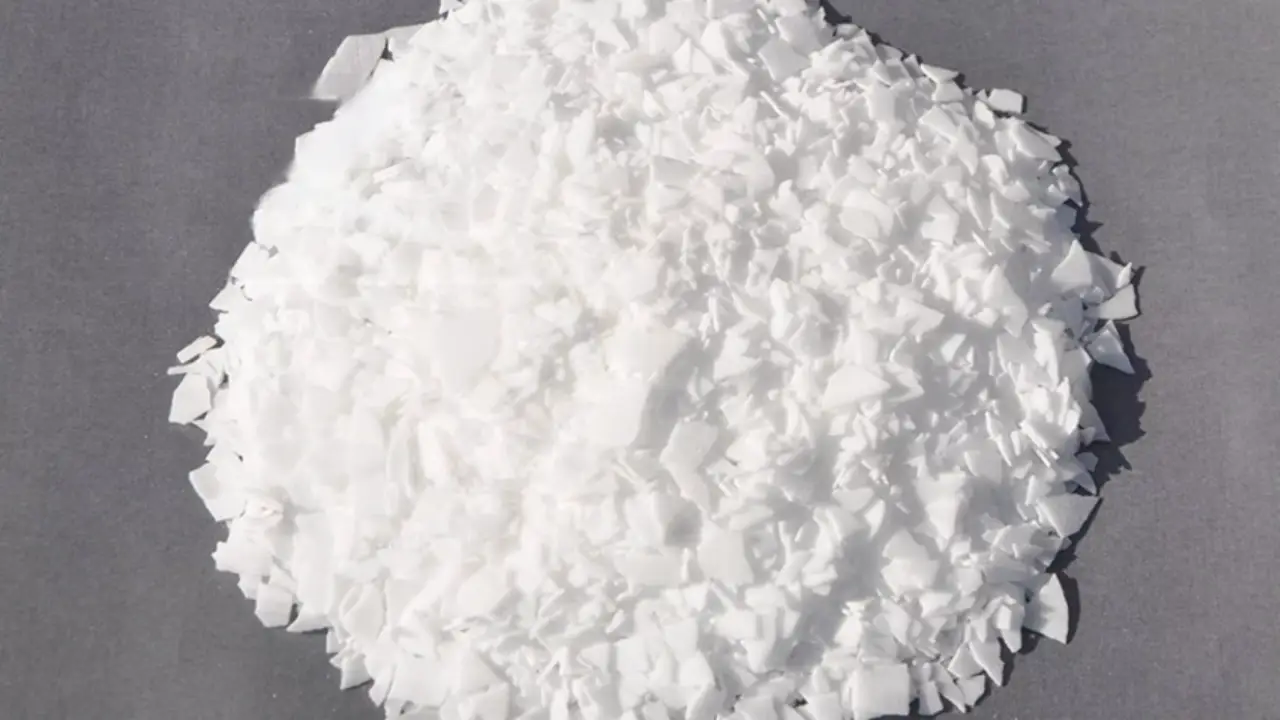

Appearance: White or pale yellow crystalline solid (flakes or powder)

-

Molecular Weight: 148.11 g/mol

-

Melting Point: 131°C

-

Boiling Point: 295°C

-

Solubility: Slightly soluble in water (0.2 g/100 mL), highly soluble in alcohols and benzene

-

Reactivity: Hydrolyzes to phthalic acid, forming esters for plasticizers and resins

-

Thermal Stability: Suitable for high-temperature processes

These characteristics make phthalic anhydride ideal for producing durable and heat-resistant chemical products.

Industrial Grades of Phthalic Anhydride

Different grades cater to diverse industrial needs:

-

Technical Grade (99.5–99.8% purity): For plasticizers and general-purpose resins

-

Purified Grade (≥99.8% purity): For high-quality coatings and dyes

-

High Purity Grade (≥99.9% purity): For pharmaceuticals and specialty resins

-

Reagent Grade (>99.9% purity): Precision synthesis and laboratory applications

Selecting the correct grade ensures optimal performance and consistency in industrial processes.

Applications of Phthalic Anhydride

Phthalic anhydride is a versatile chemical that serves as a key raw material across multiple industries. Its unique chemical properties make it essential for producing high-performance products in manufacturing, construction, automotive, pharmaceuticals, and more. Below is an in-depth look at its applications:

1. Plasticizers

Phthalic anhydride is primarily used to produce phthalate esters, which are the most common plasticizers for PVC and other polymers. These plasticizers improve flexibility, durability, and impact resistance. Applications include:

-

Automotive Parts: Flexible dashboards, hoses, seals, and flooring materials.

-

Construction Materials: PVC pipes, siding, roofing membranes, and flooring sheets.

-

Medical Devices: Tubing, blood bags, and flexible packaging.

-

Consumer Goods: Toys, footwear, and household items requiring soft, durable plastics.

2. Alkyd Resins & Coatings

Alkyd resins derived from phthalic anhydride are widely used in paints, varnishes, and coatings due to their excellent adhesion, gloss, and durability:

-

Industrial Coatings: Machinery, equipment, and automotive finishes.

-

Decorative Paints: Interior and exterior walls, wood coatings, and furniture finishes.

-

Protective Coatings: Corrosion-resistant and weatherproof coatings for metals and concrete structures.

3. Unsaturated Polyester Resins (UPR)

Phthalic anhydride is a fundamental component in unsaturated polyester resins, widely used in composite materials. Its applications include:

-

Marine Industry: Boats, yachts, and water tanks due to excellent chemical resistance.

-

Construction: Panels, pipes, and structural components.

-

Automotive: Body panels, bumpers, and interior components.

-

Electrical & Electronics: Insulating parts, switchgear, and circuit boards.

4. Dyes and Pigments

Phthalic anhydride acts as an intermediate in the production of a wide variety of azo dyes, pigments, and colorants:

-

Textile Industry: Vibrant and stable colors for cotton, polyester, and blended fabrics.

-

Plastic Coloring: Masterbatches and colored polymer compounds.

-

Printing Inks: Durable inks for paper, packaging, and industrial applications.

5. Pharmaceuticals

In pharmaceutical synthesis, phthalic anhydride is used as a key intermediate:

-

Production of anti-inflammatory drugs, analgesics, and intermediates for specialty pharmaceuticals.

-

Acts as a reagent in synthesizing functional molecules with specific chemical properties.

6. Agricultural Chemicals

Phthalic anhydride serves as a precursor for herbicides, fungicides, and pesticide formulations, enhancing the efficacy and stability of active ingredients:

-

Improves solubility and formulation consistency for crop protection products.

-

Ensures controlled release of active ingredients in agricultural applications.

7. Specialty Chemical Intermediates

It is widely used in producing a range of high-value chemical intermediates:

-

Dicarboxylic Acid Derivatives: For adhesives, sealants, and polymer crosslinkers.

-

Plastic and Rubber Additives: Improves thermal stability and mechanical performance.

-

Chemical Research: Reagent-grade phthalic anhydride is used in laboratories for advanced synthesis.

8. Industrial Adhesives and Molding Compounds

Phthalic anhydride-based resins are integral to adhesives and molding compounds:

-

Laminates and fiber-reinforced plastics for industrial machinery.

-

Hot-melt adhesives for packaging, woodworking, and construction.

-

Molded products with high heat resistance and mechanical strength.

9. Functional Coatings

Phthalic anhydride contributes to fire-retardant, anti-corrosion, and waterproof coatings:

-

Protective paints for steel structures, pipelines, and industrial equipment.

-

Fire-resistant panels and coatings for construction and transportation.

-

Coatings for containers, tanks, and storage systems that require chemical resistance.

Production Process

The production of phthalic anhydride typically involves:

-

Oxidation: Catalytic oxidation of ortho-xylene or naphthalene using vanadium pentoxide (V₂O₅)

-

Purification: Distillation removes by-products like CO₂

-

Crystallization: Solvent-based refinement achieves the desired grade

-

Drying & Packaging: Moisture removal ensures stability; available in bulk or bagged forms

This process ensures consistent quality and high purity for industrial applications.

Safety Guidelines

Proper handling is essential due to phthalic anhydride’s reactive nature:

-

Personal Protective Equipment (PPE): Gloves, goggles, and respirators prevent skin, eye, or respiratory exposure

-

Storage: Store in cool, dry areas away from oxidizers

-

Emergency Measures: Rinse exposed areas with water immediately; seek medical attention if necessary

-

Regulatory Compliance: Follow OSHA and REACH standards for safe handling, transport, and disposal

All shipments from reputable suppliers include Safety Data Sheets (SDS) and comply with global safety regulations.