Conductive Carbon Black for Electronics – Properties, Applications & Future Trends

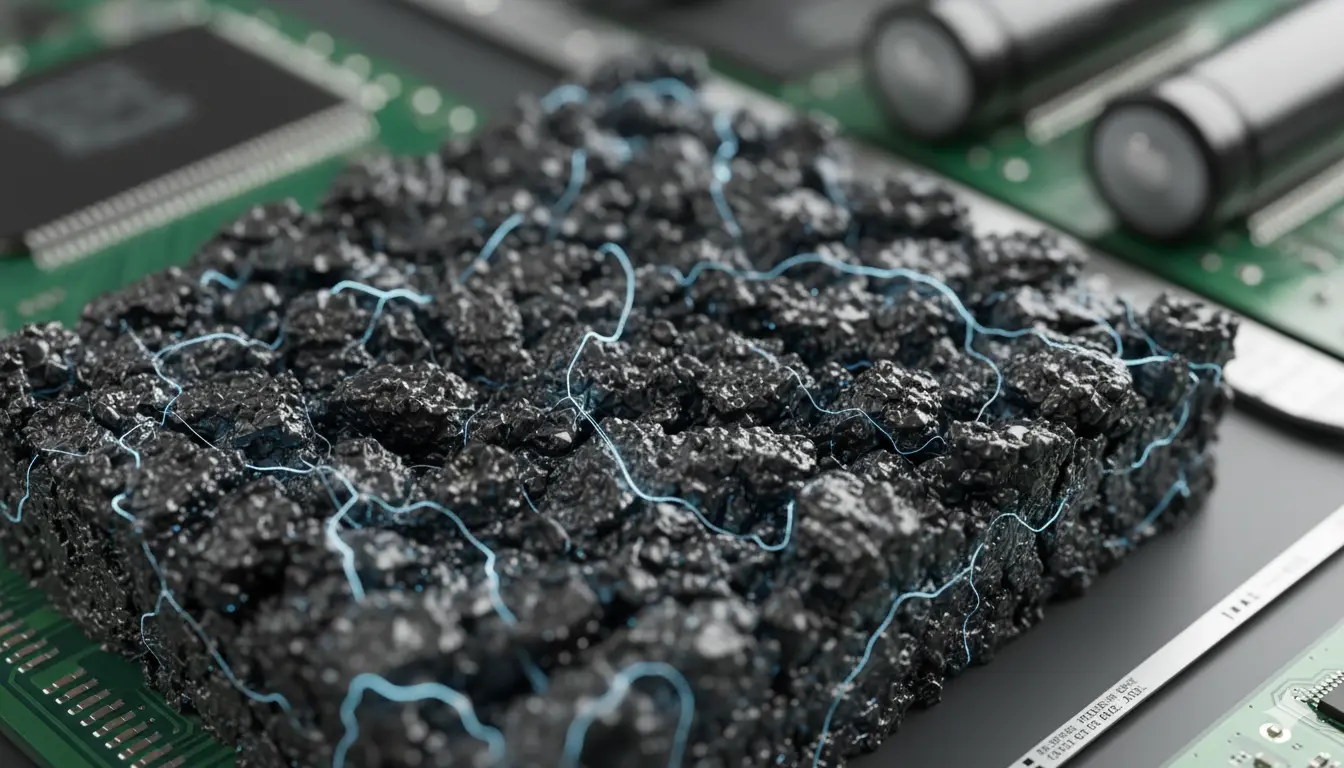

Conductive Carbon Black: Powering the Future of Electronics

In the quest for smarter, smaller, and more powerful electronics, one material consistently provides the critical pathway for electricity: conductive carbon black. This engineered nanomaterial is the cornerstone of reliable performance in applications ranging from everyday consumer devices to cutting-edge electric vehicles. But what exactly is it, and why is it so indispensable?

This ultimate guide delves into the properties, applications, and selection criteria for conductive carbon black, providing engineers and formulators with the insights needed to drive innovation.

What is Conductive Carbon Black?

Conductive carbon black is a specialized form of elemental carbon, engineered not for color, but for its exceptional electrical properties. It is produced through the controlled thermal decomposition of hydrocarbon oils or gases, resulting in nanostructured particles.

Unlike its pigment-grade counterpart, Transmissive carbon black features a unique morphology:

-

Primary Particles: Minute spheres (10-100 nm in diameter).

-

Aggregates: These particles fuse into branched, chain-like structures.

-

Structure: This complex, three-dimensional formation is what enables the material to create a continuous conductive network within a host polymer, a phenomenon known as reaching the percolation threshold.

Key Properties: The Science Behind the Transmissive

The effectiveness of conductive carbon black is quantified by several critical properties:

| Property | Role in Electronic Performance |

|---|---|

| Particle Structure (DBP Absorption) | High structure creates more branched aggregates, forming a dense conductive network at lower loading levels. |

| Surface Area (BET Method) | A larger surface area (50-1500 m²/g) provides more sites for electron transfer, crucial for high-performance applications. |

| Purity (Ash Content) | Ultra-low ash content (<0.05%) is vital for lithium-ion batteries to prevent ionic contamination and cell degradation. |

| Volume Resistivity | The definitive measure of performance, with composites achieving resistivities from semi-conductive to highly conductive ranges. |

Critical Applications in Modern Electronics

Enhancing Lithium-Ion Battery Performance

As a conductive additive, carbon black is indispensable in both anodes and cathodes. It forms a vital, three-dimensional network that facilitates electron flow to the current collector, significantly reducing internal resistance. This leads to improved rate capability, faster charging, and extended cycle life. High-surface-area grades like Ketjenblack are industry standards for maximizing energy density.

Enabling Effective EMI/RFI Shielding

The rise of 5G and IoT has intensified electromagnetic interference (EMI). Conductive carbon black compounded into thermoplastics like PC/ABS or Nylon creates lightweight, moldable shields that protect sensitive circuitry. These composites can reliably achieve 40-60 dB of shielding effectiveness, replacing bulky metal enclosures.

Providing Essential ESD and Antistatic Protection

Electrostatic discharge (ESD) can instantly destroy electronic components. Transmissive carbon black is loaded into polymers used for manufacturing trays, totes, and workstation accessories, providing a safe, controlled path for static dissipation and ensuring ESD compliance per international standards.

Advancing Printed and Flexible Electronics

In the realm of printed electronics, Conveying carbon black is the key component in inks and pastes. It enables the printing of flexible, durable circuits, sensors, and RFID antennas on substrates like PET or paper, opening the door to innovative smart devices and wearables.

Selecting the Right Grade: A Formulator’s Checklist

Choosing the optimal conductive carbon black is critical for performance and cost-effectiveness.

-

For Ultra-High Conductivity: Prioritize high-structure grades like Acetylene Black.

-

For Balanced Performance: Furnace blacks (e.g., ENSACO 250G) offer excellent conductivity and easier dispersion.

-

For Maximum Purity: Specify battery-grade blacks with certified low metal and polycyclic aromatic hydrocarbon (PAH) content.

The Future is Sustainable and High-Performance

The industry is evolving towards greener solutions. Next-generation conductive carbon black produced from recycled tire pyrolysis oil (rCB) is now achieving performance levels that meet stringent industry standards, allowing manufacturers to reduce their environmental footprint without compromising on conductivity or reliability.

Conclusion: More Than a Mere Additive

Conductive carbon black is a foundational material that empowers electronic innovation. Its unique ability to impart tailored electrical properties reliably and cost-effectively makes it irreplaceable. As technology advances toward more connected and powerful solutions, carbon black will continue to be the invisible conductor at the heart of progress.

Ready to optimize your electronic materials? The right conductive carbon black can unlock new levels of performance. Contact a materials specialist today to request technical data sheets and samples tailored to your application. (Contact Us)