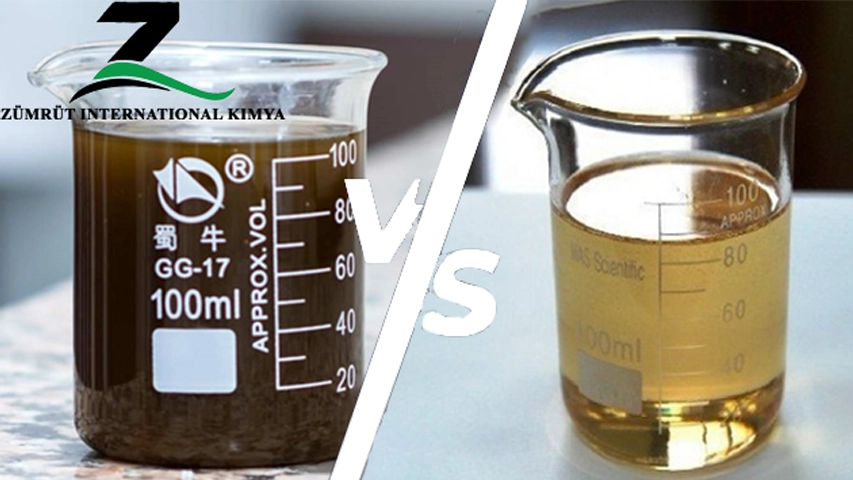

Difference between LABSA and LAB

Introduction:

Linear Alkyl Benzene are two significant compounds used in petrochemicals and surfactants. Several industrial and consumer applications relate to both these chemicals. While they are chemically allied, the differences set in about various production processes, applications, and performance characteristics. Understanding the differences between these applications helps industries make informed choices about which of the two is most applicable to their needs. In the article below, the main differences between LAB and LABSA will be reviewed by explaining their intended uses, properties, and production processes.

What is LAB (Linear Alkyl Benzene)?

LAB is a generic term for one of the most current intermediates utilized in the manufacture of detergents, surfactants, and many other chemicals. It is a hydrocarbon compound from the alkylation of benzene with long-chain olefins, usually prepared by petroleum refining processes. The LAB would contain attached to the benzene ring a linear aliphatic or an alkyl group straight-chain hydrocarbon that gives special properties to this product, which renders it efficient as a surfactant in many applications.

Production of LAB:

- LAB is synthesized by the alkylation chemical reaction of benzene with linear alpha-olefins in the presence of a catalyst. This compound is then subjected to purification and distillation to obtain pure LAB. This chemical mainly finds its application as a feedstock to LABSA, which is the subsequent stage in the manufacture of detergents and cleaning agents.

Applications of LAB:

- LAB is mainly used to manufacture LABSA and LAS, which are essential ingredients for household detergents, industrial cleaners, and personal care products. Also, it is industrially used in the production of emulsifiers for textiles, paints, and coatings.

What is LABSA (Linear Alkyl Benzene Sulfonic Acid)?

LABSA (Linear Alkyl Benzene Sulfonic Acid) is the sulfonated derivative of LAB. In this process, a sulfonic acid group is introduced into the aromatic ring of the LAB compound. Consequently, the resultant LABSA becomes much more hydrophilic (water-attracting) and hence very effective as a surfactant in detergents and cleaning agents.

Production of LABSA:

- LABSA is produced by the sulfonation of LAB or Linear Alkyl Benzene with sulfur trioxide. The SO3 yields a mixture of various sulfonated products. The sulfonic acid group is added onto the linear alkyl chain, enhancing the water solubility of the compound. This is followed by the neutralization of the product with an alkali, normally sodium hydroxide, NaOH, to result in a very active end product known as sodium linear alkyl benzene sulfonate, LAS.

Applications of LABSA:

- Linear Alkylbenzene Sulfonic Acid is used as an important and versatile surfactant in the manufacture of various cleaning products such as laundry detergents, dishwashing liquids, shampoos, and industrial cleaning agents. The excellent foaming, oil, and stain removal, and overall effectiveness of LABSA as a surfactant make it an indispensable ingredient in cleaning products.

Key Differences Between LABSA and LAB:

Chemical Structure:

- LAB (Linear Alkyl Benzene) is a hydrocarbon compound with a linear alkyl group attached to a benzene ring.

- LABSA (Linear Alkyl Benzene Sulfonic Acid) is the sulfonated version of LAB, where a sulfonic acid group is attached to the benzene ring.

Production Process:

- LAB is produced by the alkylation of benzene with linear alpha-olefins.

- LABSA is produced by sulfonating LAB with sulfur trioxide and neutralizing the resulting sulfonated product.

Solubility and Water Interaction:

- LAB is relatively hydrophobic (does not mix easily with water).

- LABSA is more hydrophilic due to the sulfonic acid group, making it highly soluble in water and effective as a surfactant.

Primary Uses:

- LAB is mainly used as a precursor in the production of LABSA and other chemicals.

- LABSA is a key component in detergents, cleaning agents, and other surfactant-based products.

Surfactant Properties:

- LAB itself is not used directly in cleaning products but is essential in the formulation of LABSA.

- LABSA is a powerful surfactant, commonly used in laundry detergents, dishwashing liquids, and other cleaning solutions due to its excellent foaming and cleaning capabilities.

Conclusion:

The differences in LAB and LABSA come in terms of the chemical structure, routes of production, and applications. While LAB is the raw material in the manufacture of Linear Alkyl Benzene Sulfonate, in turn, LABSA is used as an active surfactant in many cleaning and industrial applications. This will help them understand which one to choose for their products to optimize both performance and cost.

Knowledge of the differences between LAB and LABSA determines the method of product development that a manufacturer in the detergent, personal care, or industrial cleaning sectors will apply to suit both quality and effectiveness. The properties of each compound can be utilized by manufacturers in response to rising demands for quality cleaning with considerations toward the safety of the product and compatibility with the environment.

For further inquiries or to explore LABSA and LAB-based products, contact ZÜMRÜT International Kimya Co., a leading provider of petrochemical products for industrial applications.