Supplier of Polybutadiene Rubber From Turkey and Dubai UAE

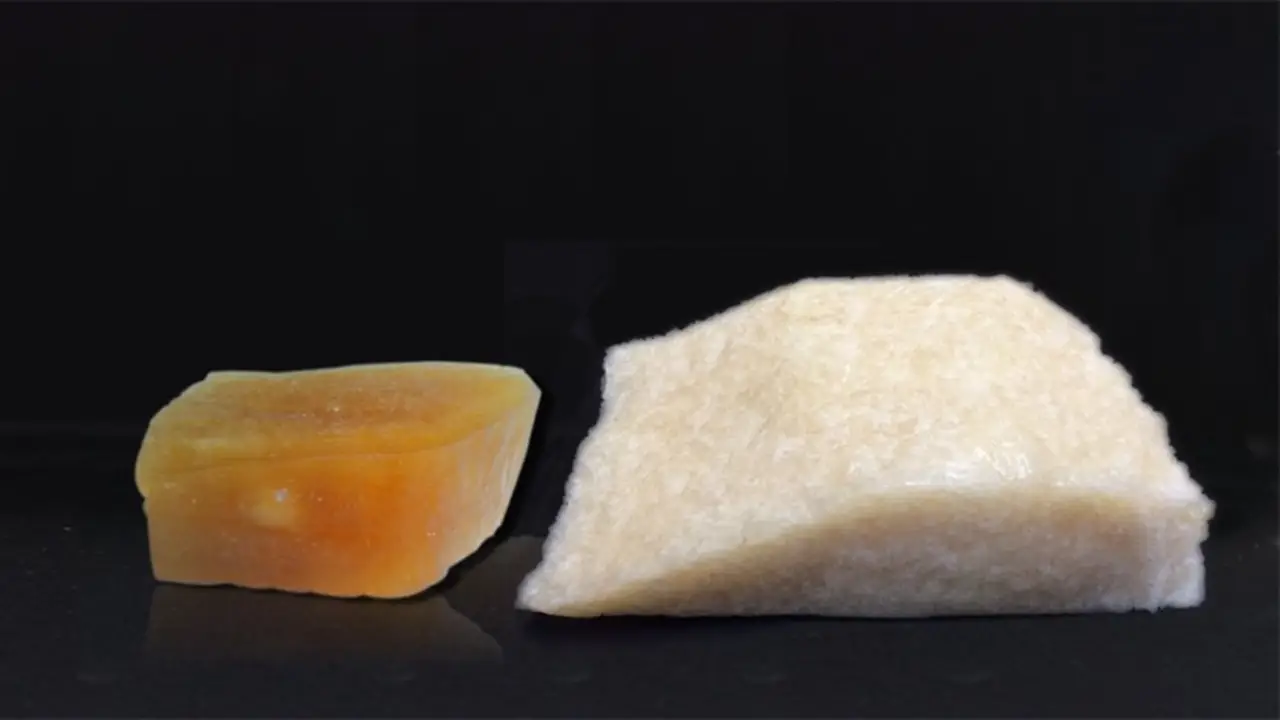

Description of Polybutadiene Rubber (PBR)

Polybutadiene Rubber (PBR) is a synthetic rubber produced through the polymerization of butadiene monomers. Known for its exceptional elasticity, durability, and resistance to wear, PBR is widely used across tires, automotive components, industrial applications, and consumer products.

Key Characteristics of PBR:

-

High Resilience: Excellent elasticity and rebound performance.

-

Low Glass Transition Temperature: Maintains flexibility even at low temperatures.

-

Wear Resistance: Highly resistant to abrasion, ideal for high-wear environments.

-

Low Hysteresis: Minimizes energy loss, improving efficiency in tires and mechanical applications.

-

Aging Resistance: Durable under long-term exposure, especially when combined with stabilizers.

Types of Polybutadiene Rubber:

-

High Cis Polybutadiene: High proportion of cis-1,4 units for superior resilience and low-temperature performance.

-

Low Cis Polybutadiene: Balanced trans-1,4 and vinyl-1,2 units for specific mechanical properties.

-

High Vinyl Polybutadiene: Contains significant 1,2-vinyl units for specialized applications.

Applications and Uses of Polybutadiene Rubber (PBR)

1. Tire Manufacturing

PBR’s high resilience and low rolling resistance make it ideal for tire production, improving fuel efficiency, tread durability, and sidewall flexibility.

2. Footwear

Used in the soles of shoes for wear resistance, elasticity, and comfort, enhancing the lifespan of footwear products.

3. Golf Balls

Its elasticity and impact resistance make PBR a preferred material for the core of golf balls, ensuring optimal performance and durability.

4. Automotive Parts

PBR is used in hoses, belts, seals, and gaskets due to its high durability, flexibility, and resistance to wear.

5. Industrial Applications

-

Conveyor Belts: Provides abrasion resistance and extended service life.

-

Vibration Mounts: Absorbs vibrations effectively for industrial machinery.

-

Rollers and Tubing: Offers flexibility and durability in manufacturing equipment.

6. Plastic Modification

PBR enhances impact resistance when blended with plastics such as polystyrene and ABS.

7. Adhesives and Sealants

Used in pressure-sensitive adhesives for tapes, labels, and rubber-based sealants.

8. Miscellaneous Applications

-

Sporting goods, rubber bands, and cable insulation.

-

Polyethylene Wax can be used in combination with PBR in certain plastic and adhesive formulations to improve processing and surface properties, enhancing the final product performance.

Packing and Storage of Polybutadiene Rubber

Packing Options:

-

180 kg drums (new or used)

-

ISO tanks and flex tanks for bulk shipments

-

Each 20-foot container can hold up to 80 drums

Storage Guidelines:

-

Temperature Control: Store at 15–25°C (59–77°F), avoiding heat sources.

-

Humidity Control: Store in dry conditions; avoid direct contact with water.

-

Light Protection: Store in dark or opaque packaging to prevent UV degradation.

-

Chemical Safety: Keep away from strong acids, bases, oxidizing agents, and solvents.

-

Handling: Store in sealed containers, handle gently, and avoid contamination.

Safety and Handling

-

Wear gloves and protective goggles when handling PBR.

-

Ensure proper ventilation in storage and processing areas.

-

Avoid inhalation of dust or contact with contaminated surfaces.

Technical Parameters of PRB

Rubber Technical Parameters

| Parameters | Units | Values | Test methods |

|---|---|---|---|

| Mooney viscosity ML 1+4 (100°C) – massed | °ML | 58 ÷ 68 | ISO 289 |

| Volatile matters | % wt | max. 0,8 | ISO 248 |

| Total ash | % wt | max. 0,7 | ISO 247 |

| 1,4 cis structure content | % | min. 96 | ISO 12965 |

| Antioxidant content | % wt. | min. 0,3 | Own method |

Parameters of the vulcanizate

| Parameters | Units | Values | Test methods |

|---|---|---|---|

| ML | dNm | 2,5 ÷ 4,5 | ISO 6502 |

| MH | dNm | 19,5 ÷ 23,5 | ISO 6502 |

| Ts1 | min. | 1,5 ÷ 3,0 | ISO 6502 |

| Column 1 Value 4 | Column 2 Value 4 | Column 3 Value 4 | Column 4 Value 4 |

| Tc90 | min. | 7,5 ÷ 12,5 | ISO 6502 |