Supplier of Polyethylene Wax (PE-WAX) from Turkey and Dubai-UAE

Polyethylene Wax (PE Wax): Overview

Seeking a versatile additive to enhance plastic processing, coating durability, and rubber performance? Polyethylene wax (PE wax) is the industry’s high-performance secret, used by 75% of masterbatch manufacturers to reduce production defects by up to 30% and energy consumption by 15%. This definitive technical guide covers everything from HDPE wax specifications to proven applications in PVC pipes, inks, and hot-melt adhesives—plus expert sourcing tips from leading suppliers.

What is Polyethylene Wax?

Polyethylene wax is a low molecular weight synthetic thermoplastic polymer derived from polymerized ethylene, engineered for exceptional hardness, thermal stability, and compatibility. This high-performance processing aid offers a unique combination of properties: melting points range from 110 °C to 130°C, depending on the grade, density varies between 0.92 and 0.97 g/cm³, and molecular weights span 2,000 to 10,000 g/mol.

Unlike standard paraffin waxes, PE wax offers superior dispersing agent capabilities and surface-modifying properties that make it indispensable across manufacturing sectors. The chemical formula (C₂H₄)ₙ features polymer chains that provide excellent chemical resistance and low shrinkage characteristics. Suppliers typically stock white to yellowish powder, granule, or pellet forms, with oxidized grades offering acid values of 15-30 mg KOH/g for enhanced polarity.

Types and Grades of Polyethylene Wax

Selecting the optimal grade ensures maximum performance. Here’s how experts categorize products:

High-Density Polyethylene (HDPE) Wax

Description: Harder wax with molecular weight of 6,000-10,000 g/mol and density >0.95 g/cm³. Offers exceptional mold release properties and wear resistance at temperatures up to 150°C.

Primary Applications:

-

Plastic extrusion (0.5-2% loading): Reduces die build-up in PVC pipe manufacturing

-

Injection molding (1-3%): Improves flow index and surface gloss

-

Masterbatch carrier (5-10%): Ensures uniform pigment dispersion for color concentrates

Low-Density Polyethylene (LDPE) Wax

Description: Softer wax with molecular weight of 2,000-5,000 g/mol. Provides excellent flexibility and lubricant properties in low-viscosity systems.

Primary Applications:

-

Coatings & paints (2-5%): Enhances scratch resistance and mar-proofing

-

Hot-melt adhesives (5-15%): Modifies viscosity and open time

-

Rubber processing (1-2%): Acts as internal dispersing agent for fillers

Oxidized Polyethylene Wax

Description: Chemically modified with polar carboxyl groups (acid value 15-30 mg KOH/g) for enhanced compatibility with polar polymers and superior pigment dispersion.

Primary Applications:

-

PVC processing (0.8-1.5%): Critical for rigid PVC pipes and profiles

-

Printing inks (2-4%): Prevents pigment flooding and settling

-

Polish formulations (3-8%): Boosts gloss and anti-blocking properties

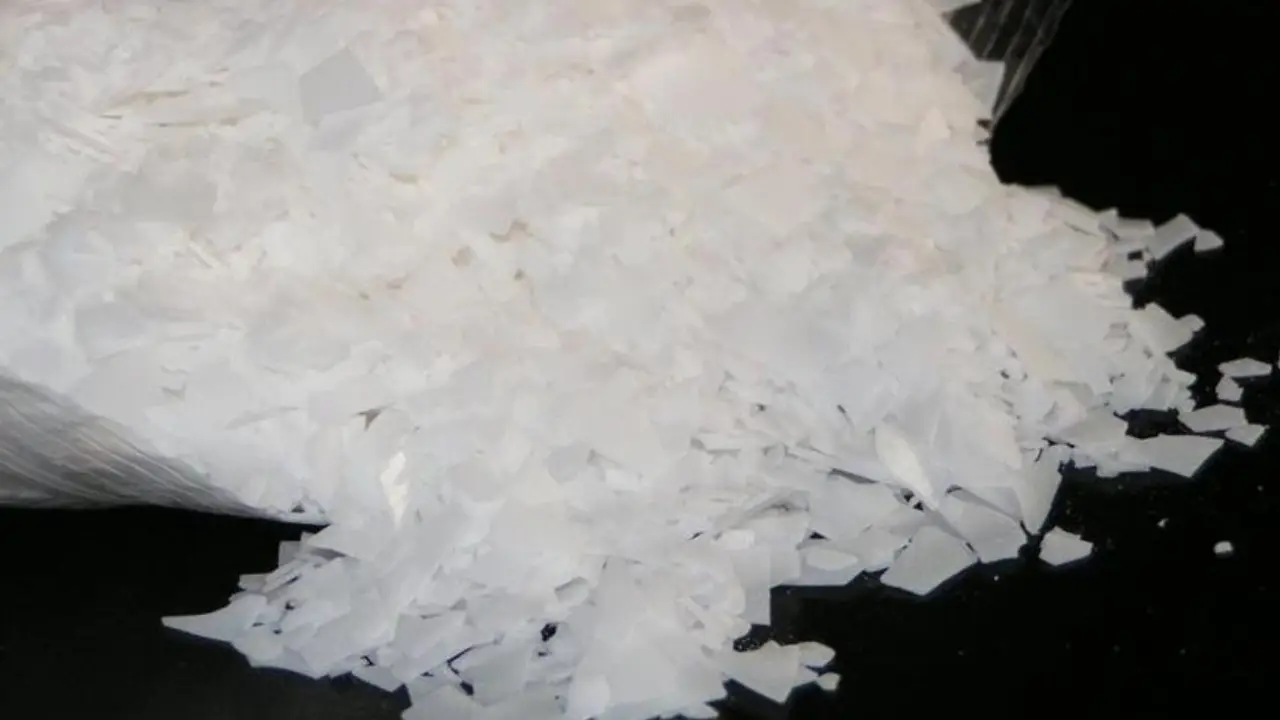

Forms of Polyethylene Wax: Powder, Flakes & Pastilles

Polyethylene wax is manufactured in three primary physical forms, each optimized for specific handling systems and application requirements.

| Form | Description | Key Advantages | Best Applications |

|---|---|---|---|

| PE Wax Powder | Fine micronized powder (10-100 microns) with the fastest dissolution rate | Rapid melting, superior dispersion, and dosing flexibility | Powder coatings (2-4%), masterbatch powders, PVC dry-blends |

| PE Wax-Flakes | Flat plate-like particles (1-5 mm diameter) offering the best cost-performance ratio | Low dust, good flowability, cost-effective | Hot-melt adhesives, plastics compounding, solvent-based coatings |

| PE Wax-Pastille | Small bead-like spheres (2-5 mm diameter) for premium, dust-free handling | Dust-free, precise metering, consistent melting | Automated plastic processing, food-contact packaging, and pharmaceuticals |

Selection Guidance: Match form to your feeding equipment and safety requirements. Most suppliers stock all three forms for each grade.

Applications of Polyethylene Wax by Industry

Plastics & Polymers Processing

As a processing aid in thermoplastics, polyethylene wax delivers measurable performance improvements. In polyolefin film production, adding 0.5-1.5% PE wax reduces the coefficient of friction by 40-60%, preventing film blocking. For engineering plastics like nylon 6 and PET, PE wax at 1-2% loading prevents melt fracture and extends production runs by up to 50% between cleanings.

Wood-plastic composite (WPC) manufacturers rely on 1-3% PE wax to improve throughput by 20-25% while reducing equipment wear. In PVC pipe extrusion, oxidized PE wax at 0.8-1.2% acts as a crucial mold release agent, cutting extrusion torque by 15% and improving surface finish. Technical teams recommend grade-specific formulations for recycled PP/PE processing, where PE wax at 2-3% restores degraded flow properties.

Rubber Industry Applications

Polyethylene wax serves multiple functions that translate to direct cost savings. As an external lubricant in tire manufacturing, spraying 2-5% PE wax dispersion on molds eliminates sticking and reduces defect rates from 3% to under 0.5%. In EPDM seal production, incorporating 1-2% LDPE wax during mixing improves mold flow and creates a uniform glossy finish.

Coatings, Inks & Polishes

In powder coatings, adding 2-4% PE wax improves fluidization during spray application, ensuring a consistent film thickness of 60-80 microns. For flexographic and gravure printing inks, oxidized polyethylene wax at 2-3% concentration stabilizes pigment concentrates, preventing flooding during 24-hour press runs. This dispersing agent capability reduces solvent usage by 10% while improving print definition.

Adhesives & Sealants

Hot-melt adhesive formulators rely heavily on polyethylene wax as a viscosity modifier. In packaging adhesives, adding 5-12% LDPE wax reduces melt viscosity by 30-40%, allowing temperature reduction from 180°C to 160°C. For pressure-sensitive adhesives, 3-8% PE wax adjusts peel strength, creating removable labels with clean release.

Cosmetics & Personal Care

FDA-compliant polyethylene wax grades (21 CFR 177.1520) serve as critical functional ingredients. In lipstick formulations, PE wax at 3-8% provides structure and improves pay-off, maintaining break strength above 300 grams. For creams and lotions, micronized PE wax at 0.5-1.5% acts as an emollient creating silky skin feel.

Key Benefits of Polyethylene Wax

-

Superior Processing Efficiency: Reduces torque and energy consumption by 10-15% in extrusion

-

Enhanced Product Quality: Improves surface gloss by 20-30% and eliminates sharkskin defects

-

Cost Optimization: Decreases production defects and downtime, delivering ROI within 2-3 production cycles

-

Versatile Compatibility: Works seamlessly with PE, PP, PVC, PS, ABS, and rubber compounds

-

Regulatory Compliance: FDA 21 CFR 175.105 approved for indirect food contact applications

Polyethylene Wax vs. Alternative Waxes

| Feature | PE Wax | Paraffin Wax | Fischer-Tropsch Wax |

|---|---|---|---|

| Molecular Weight | 2,000-10,000 | 300-600 | 500-1,200 |

| Melting Point | 110-130°C | 55-70°C | 95-115°C |

| Hardness | High | Low | Medium |

| Pigment Dispersion | Excellent | Poor | Good |

| Best For | High-performance processing | Candle making | Premium coatings |

Key Advantage: PE wax offers 30-40% better thermal stability than paraffin, making it irreplaceable in high-temperature plastic processing.

Global Market Insights & Sourcing Tips

The global polyethylene wax market shows strong growth, with Asia-Pacific accounting for 40% of demand. Leading production regions include:

-

China: Largest producer, competitive pricing for LDPE grades

-

Germany: Premium HDPE wax for automotive applications

-

USA: Specialized oxidized PE wax for FDA-compliant uses

Major producers include: BASF, Honeywell, Clariant, and Mitsui Chemicals.

When selecting a supplier, verify:

-

ISO 9001 certification and batch consistency (COA documents)

-

Minimum order quantities (MOQ: typically 1 MT for custom grades)

-

Lead times: 2-4 weeks for standard grades, 6-8 weeks for modified waxes

-

Technical support for formulation optimization

Handling, Storage, and Safety Guidelines

Storage Requirements

-

Store in cool, dry, ventilated areas below 35°C

-

Keep away from direct sunlight and moisture sources

-

Shelf life: 24 months sealed, 12 months after opening

-

Avoid stacking pallets above 3 meters to prevent compaction

Handling Precautions

-

PPE: Use dust masks (N95) and safety goggles during bag emptying

-

Ventilation: Ensure local exhaust ventilation in mixing areas

-

Spill Response: Sweep dry; avoid water contamination

-

Fire Safety: Dust explosion risk—keep away from ignition sources

Regulatory Status

-

REACH: Exempt as polymer (EC 1907/2006)

-

FDA: Approved under 21 CFR 177.1520

-

RoHS: Compliant for electronics applications

Ready to Optimize Your Formulation?

Premium polyethylene wax can transform your production efficiency and product quality. Our network of verified suppliers provides:

-

Free technical consultations and grade selection support

-

Sample kits (5 kg) for R&D testing

-

Certificate of Analysis (COA) for every batch

-

Competitive bulk pricing for orders above 10 MT

-

Fast shipping: 2-week delivery to North America, 3-4 weeks to Europe

Contact Us Today:

[Request Your Free Sample & Technical Data Sheet] | [Get Bulk Quote in 24 Hours] | Call Technical Support: +971 50 720 9246