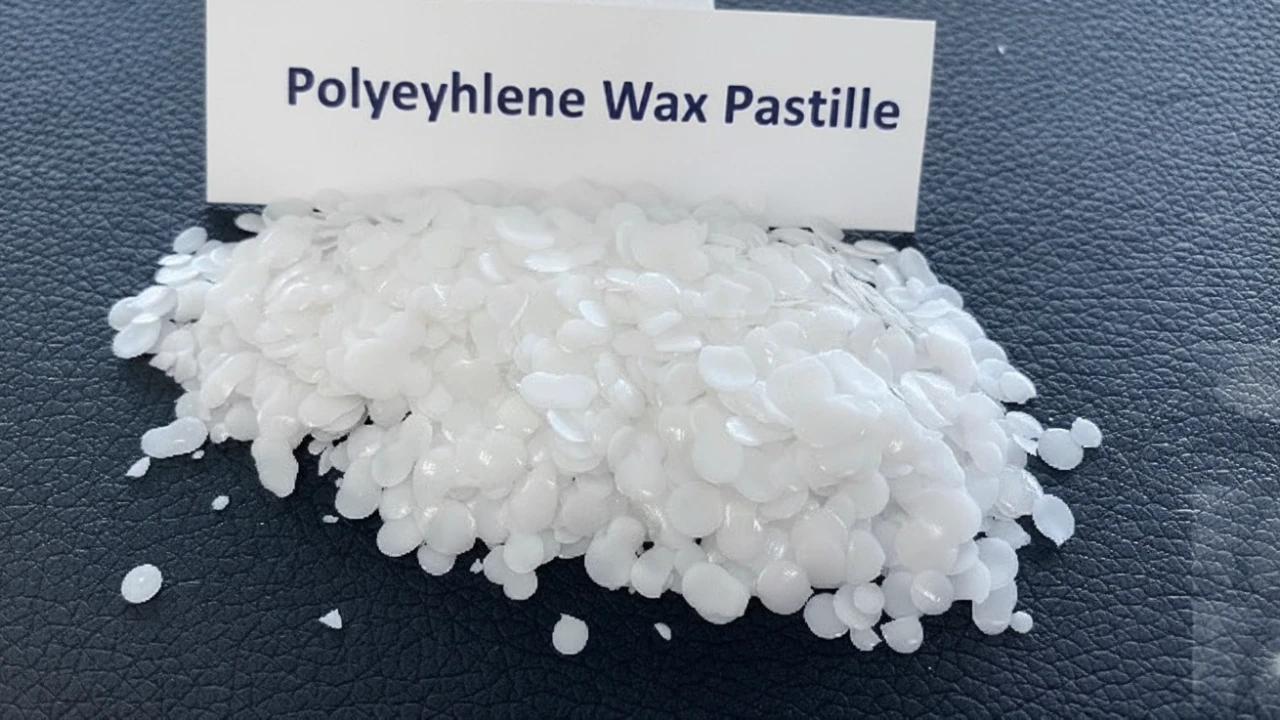

Polyethylene Wax Pastille Supplier From Turkey And Dubai-UAE

Introduction

Polyethylene Wax Pastille is a high-performance thermoplastic polymer widely used in plastics, coatings, adhesives, and other industrial applications. As a low molecular weight polyethylene, these pastilles are designed for easy handling, consistent dosing, and improved process efficiency. Known for their excellent lubrication, chemical stability, and thermal resistance, polyethylene wax pastilles enhance product performance and manufacturing productivity.

What is Polyethylene Wax Pastille?

Polyethylene Wax Pastille is a solid form of polyethylene wax, typically produced by polymerization of ethylene or by thermal degradation of high molecular weight polyethylene. Unlike powder or granules, pastilles are uniform, free-flowing, and easy to handle, reducing dust and simplifying processing.

Key properties of polyethylene wax pastilles include:

-

High Melting Point: Typically ranges from 100–140°C, suitable for high-temperature processes.

-

Excellent Lubricity: Reduces friction during extrusion, molding, or calendaring.

-

Chemical Inertness: Compatible with plastics, rubbers, adhesives, and coatings.

-

Consistent Particle Size: Ensures uniform dispersion and reliable dosing.

-

Thermal Stability: Maintains performance in extreme temperature conditions.

LSI keywords: thermoplastic wax, low molecular weight polyethylene, industrial polymer, polymer additive, pastille form polyethylene wax.

Types and Grades of Polyethylene Wax Pastille

Polyethylene wax pastilles are available in different grades to meet diverse industrial requirements:

-

Oxidized Polyethylene Wax Pastille: Modified with oxygen-containing groups, providing enhanced compatibility with polar materials. Ideal for coatings, inks, adhesives, and paints.

-

Non-Oxidized Polyethylene Wax Pastille: High purity and chemically inert, commonly used in plastics, rubber, and masterbatches where minimal reactivity is required.

-

High-Density Polyethylene (HDPE) Wax Pastille: Hard and thermally stable, suitable for molding, coatings, and candle applications.

-

Low-Density Polyethylene (LDPE) Wax Pastille: Flexible and low viscosity, used in hot-melt adhesives, plastics lubrication, and film extrusion.

-

Custom Grades: Tailored melting points, density, or chemical modifications to meet specific industrial requirements.

Applications of Polyethylene Wax Pastille

Polyethylene wax pastilles are highly versatile and serve multiple industrial sectors:

Plastics and Rubber

-

Acts as an internal and external lubricant during extrusion and molding.

-

Reduces friction and wear on machinery, improving efficiency and product quality.

-

Enhances release properties and prevents sticking during demolding.

Coatings and Inks

-

Serves as a matting agent, scratch-resistant additive, and surface smoother.

-

Improves dispersion of pigments, enhancing gloss and abrasion resistance.

-

Supports high-speed printing processes with a uniform surface finish.

Adhesives and Sealants

-

Enhances thermal stability, flexibility, and water resistance of adhesives.

-

Reduces viscosity in hot-melt formulations, ensuring smooth application.

-

Improves bonding and durability in pressure-sensitive adhesives and sealants.

Masterbatches and Pigments

-

Ensures uniform dispersion of additives and colorants.

-

Enhances color vibrancy, processing efficiency, and surface quality of molded products.

Personal Care and Cosmetics

-

Used in formulations such as lipsticks, creams, and lotions for a smooth texture.

-

Provides water resistance and improved emollient properties without altering stability.

Candles and Wax Products

-

Increases hardness, burn time, and surface finish of candles.

-

Enhances polishes, coatings, and wax blends for industrial or decorative use.

Advantages of Polyethylene Wax Pastille

-

Easy Handling: Uniform pastille form reduces dust and simplifies dosing.

-

Process Efficiency: Enhances extrusion, molding, and coating processes.

-

Improved Product Performance: Enhances surface finish, abrasion resistance, and durability.

-

Chemical and Thermal Stability: Performs reliably under harsh conditions.

-

Versatility: Suitable for plastics, rubbers, coatings, adhesives, and personal care.

-

Sustainability: Compatible with recyclable and eco-friendly manufacturing processes.

Packaging of Polyethylene Wax Pastille

Polyethylene wax pastilles are packaged to ensure product integrity and ease of transport:

-

25 kg Bags: Multi-layered paper bags with polyethylene liners for medium-scale industrial use.

-

500 kg Jumbo Bags: Durable woven polypropylene bags designed for bulk transport.

-

Custom Packaging: Available to meet unique industrial or shipping requirements.

Packaging ensures protection from moisture, contamination, and mechanical damage, keeping the pastilles ready for immediate use.