The Role of Caustic Soda Flakes in Textile Industry

Unlocking the Power of Caustic Soda in the Textile Industry

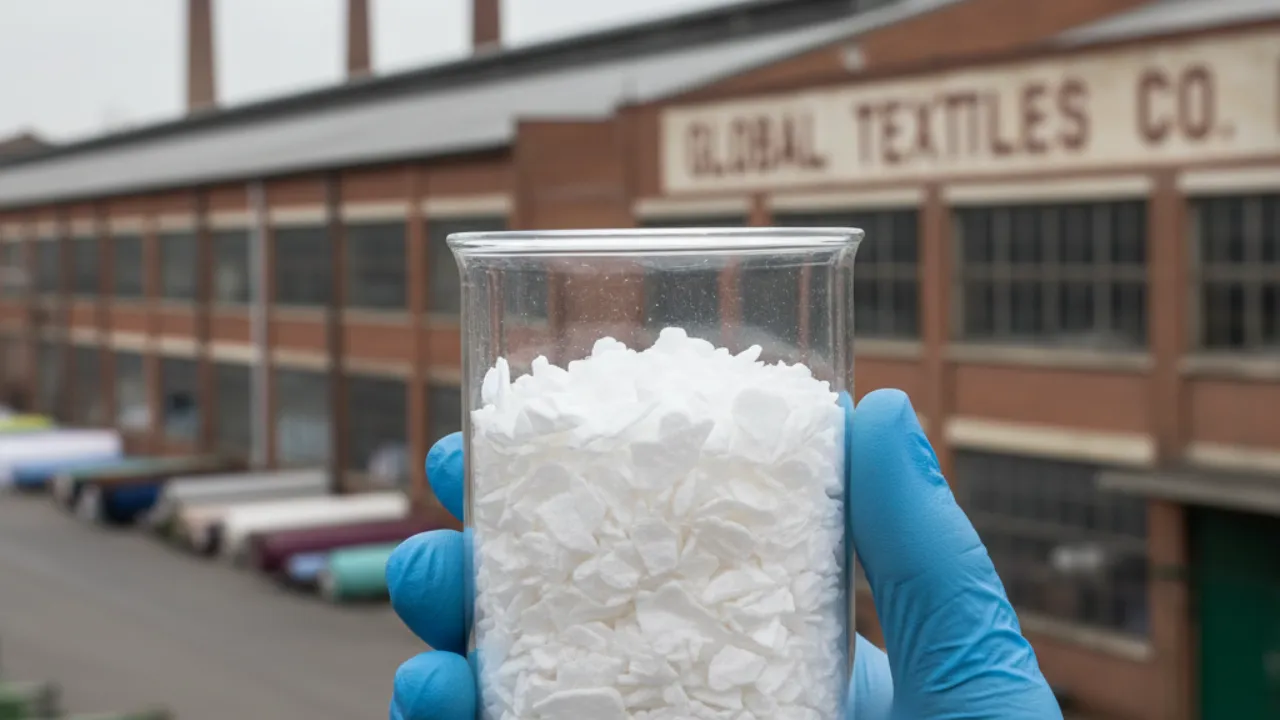

In the dynamic world of textile processing, caustic soda—also known as sodium hydroxide (NaOH)—stands as a cornerstone chemical. Often supplied in flake form for ease of handling and dissolution, caustic soda in the textile industry plays a pivotal role in transforming raw fibers into high-quality fabrics. From cotton scouring to advanced dyeing techniques, this versatile alkali is indispensable for achieving the desired texture, colorfastness, and durability in end products. As global demand for sustainable and efficient textile manufacturing rises, understanding the applications, benefits, and best practices for caustic soda usage becomes crucial for industry professionals and innovators alike.

This comprehensive guide explores the multifaceted contributions of caustic soda flakes to textile production, highlighting its chemical properties, key processes, and emerging trends. Whether you’re a mill operator, fabric designer, or supply chain manager, delving into these insights will equip you with the knowledge to optimize operations and elevate product quality.

What Is Caustic Soda and Why Is It Vital for Textile Manufacturing?

Caustic soda, or sodium hydroxide flakes, is a strong alkaline compound produced through the electrolysis of sodium chloride brine. Its high solubility in water and potent reactivity make it an ideal agent for breaking down impurities and modifying fiber structures in textile wet processing.

In the textile sector, caustic soda serves as a primary alkali for several reasons:

- pH Regulation: It effectively raises the pH of processing baths, enabling controlled chemical reactions essential for fiber treatment.

- Impurity Removal: As a powerful saponifier, it hydrolyzes natural waxes, pectins, and oils on raw fibers, ensuring cleaner substrates for subsequent steps.

- Cost-Effectiveness: Compared to alternative alkalis like potassium hydroxide, caustic soda flakes offer superior value without compromising efficacy, making it a staple in both small-scale and large-scale operations.

Globally, the textile industry consumes millions of tons of caustic soda annually, underscoring its economic significance. According to industry reports, caustic soda accounts for up to 10-15% of chemical inputs in cotton-based textile processing alone.

Key Applications of Caustic Soda Flakes in Textile Processing

The versatility of caustic soda extends across the entire textile value chain, from preparatory stages to finishing. Below, we outline its primary uses, supported by process details and practical considerations.

1. Scouring: The Foundation of Clean Fabrics

Scouring is the initial desizing and cleaning step for natural fibers like cotton, wool, and linen. Caustic soda flakes are dissolved in hot water (typically 90-100°C) to create a 2-5% alkaline bath, which removes non-cellulosic impurities such as seed fragments, fats, and starches.

- Process Parameters: Maintain a liquor ratio of 1:20-1:30, with treatment times of 1-2 hours followed by thorough rinsing.

- Benefits: Enhances absorbency and whiteness index, preparing yarns for even dyeing. Without effective scouring, fabrics risk uneven coloration and reduced tensile strength.

- LSI Insight: In cotton textile processing, caustic soda scouring reduces fiber weight by 5-10%, yielding a more uniform base material.

For synthetic blends, milder concentrations (1-2%) prevent fiber degradation, balancing efficiency with sustainability.

2. Mercerization: Enhancing Fabric Strength and Luster

One of the most iconic applications of caustic soda in the textile industry is mercerization, a swelling treatment for cotton yarns and fabrics. Submerging materials in a 20-30% caustic soda solution under tension at room temperature causes cellulose fibers to swell, realigning their crystalline structure.

- Key Outcomes:

- Increased tensile strength by 20-30%.

- Improved dye affinity and luster, giving fabrics a silky sheen.

- Enhanced dimensional stability, reducing shrinkage in garments.

- Technical Tips: Tension control is critical—over-tensioning can lead to yarn breakage. Post-mercerization neutralization with dilute acid ensures pH neutrality.

- Industry Impact: Mercerized cotton commands premium pricing in apparel, from denim to dress shirts, due to its superior hand-feel and durability.

This process exemplifies how caustic soda flakes enable value-added textile innovations, directly influencing market competitiveness.

3. Bleaching and Dyeing: Achieving Vibrant, Long-Lasting Colors

In bleaching, caustic soda facilitates oxidative processes by stabilizing hydrogen peroxide or chlorine-based bleaches. A 1-3% caustic bath at 80-95°C activates the bleach, removing residual color bodies from scoured fabrics.

For dyeing, caustic soda acts as an auxiliary to fix dyes on cellulosic fibers:

- Vat and Reactive Dyes: It promotes dye hydrolysis, ensuring covalent bonding for wash-fastness.

- Process Optimization: Use 2-4% caustic soda in padding or exhaustion methods, monitoring pH at 10-11 for optimal uptake.

- Advantages Over Alternatives: Unlike weaker alkalis, caustic soda provides rapid pH shifts, shortening cycle times by up to 25% and reducing energy consumption.

Environmental note: Modern mills integrate caustic recovery systems to recycle up to 90% of the chemical, minimizing effluent loads.

4. Other Specialized Uses in Textile Finishing

Beyond core processes, caustic soda flakes support:

- Carbonization in Wool Processing: Degrades vegetable matter at 5-10% concentrations.

- Degumming Silk: Gently removes sericin proteins for finer yarns.

- pH Adjustment in Printing: Ensures paste stability for precise color application.

These applications highlight caustic soda’s adaptability across fiber types, from natural to regenerated cellulose like viscose.

Benefits and Challenges: Maximizing Efficiency with Caustic Soda

Incorporating caustic soda into textile workflows yields tangible gains:

- Quality Enhancement: Treated fabrics exhibit better moisture wicking, dye penetration, and resistance to abrasion.

- Operational Savings: Its high reactivity lowers dosage requirements, cutting costs by 15-20% per batch.

- Sustainability Edge: When paired with closed-loop systems, it supports eco-friendly practices, aligning with certifications like GOTS (Global Organic Textile Standard).

However, challenges persist:

- Corrosivity: Handle with PPE (personal protective equipment) to avoid skin burns; storage in cool, dry conditions prevents moisture absorption.

- Waste Management: High-pH effluents demand neutralization before discharge to comply with regulations like those from the EPA or EU REACH.

- Supply Chain Volatility: Fluctuations in chlor-alkali production can impact pricing, necessitating diversified sourcing.

To mitigate risks, invest in automated dosing systems and regular quality audits of caustic soda flakes for purity (typically 98-99% NaOH).

Future Trends: Innovation and Sustainability in Caustic Soda Usage

As the textile industry pivots toward green chemistry, caustic soda’s role evolves. Emerging trends include:

- Bio-Based Alternatives: Hybrid formulations blending caustic soda with enzymes for low-temperature scouring, reducing energy use by 30%.

- Digital Integration: IoT-enabled monitoring of caustic baths for real-time pH and concentration adjustments.

- Circular Economy Models: Advanced membrane technologies for caustic recovery, targeting zero-waste processing.

With the projected growth of the global textile chemicals market to $28 billion by 2028, caustic soda remains a linchpin for sustainable innovation. Industry leaders like those in India’s spinning hubs and Bangladesh’s garment clusters are already adopting these advancements to meet consumer demands for ethical production.

Conclusion: Caustic Soda as the Unsung Hero of Textiles

In summary, caustic soda in the textile industry is far more than a mere chemical—it’s the enabler of superior fabric performance and efficient manufacturing. From scouring raw cotton to mercerizing premium yarns, its applications drive quality, cost savings, and innovation. By mastering its use and addressing environmental imperatives, textile professionals can future-proof their operations in a competitive landscape.