Supplier of Caustic Soda (Sodium Hydroxide) from Turkey and Dubai-UAE

- Leading Bulk Supplier of High-Purity Sodium Hydroxide for Industrial Applications

- What is Caustic Soda (Sodium Hydroxide – NaOH)?

- Choosing Between Flakes, Pearls & Liquid: A Quick Guide

- Three Optimized Forms of Caustic Soda

- Technical Comparison Table

- Application and Uses of Caustic Soda (Sodium Hydroxide)

- Grades & Specifications

- Why Choose Our Caustic Soda Supply?

- Safety Handling Guidelines

- Customer Testimonial

- Technical Data Sheet of Caustic Soda Flakes

- Technical Data Sheet of Caustic Soda Pearls

- Technical Data Sheet of Caustic Soda Liquid

Leading Bulk Supplier of High-Purity Sodium Hydroxide for Industrial Applications

We are a leading Caustic Soda supplier and international sodium hydroxide supplier, providing high-purity NaOH in bulk quantities for industrial, commercial, and manufacturing applications worldwide. Our product portfolio includes caustic soda flakes, caustic soda pearls (prills), and liquid caustic soda, manufactured under strict quality control systems in Turkey and supplied through strategically located warehouses in Dubai (UAE).

With product purity ranging from 98% to 99.5% NaOH, ISO-certified production, REACH compliance, and batch-specific Certificates of Analysis (CoA), we ensure a stable, reliable, and compliant supply chain for customers across Europe, the Middle East, Africa, Asia and South America

What is Caustic Soda (Sodium Hydroxide – NaOH)?

Caustic Soda, chemically known as Sodium Hydroxide (NaOH), is a highly alkaline, inorganic compound widely used as a fundamental raw material in numerous industrial processes. It is produced through the chlor-alkali process, where sodium chloride (brine) is electrolyzed using modern membrane cell technology to yield sodium hydroxide, chlorine, and hydrogen.

Due to its strong alkalinity, Caustic Soda is essential for neutralizing acids, breaking down organic materials, adjusting pH levels, and driving chemical reactions across multiple industries.

Key Physical and Chemical Properties of Caustic Soda

- Chemical Formula: NaOH

- Appearance: White solid (flakes or pearls) or clear liquid (solution)

- pH Value: 13–14 (strong alkali)

- Solubility: Completely soluble in water (exothermic reaction)

- Hygroscopic Nature: Absorbs moisture and CO₂ from air

- Production Method: Membrane cell chlor-alkali process

Choosing Between Flakes, Pearls & Liquid: A Quick Guide

How to Select the Right Form for Your Process:

| Consideration | Choose Flakes If: | Choose Pearls If: | Choose Liquid If: |

|---|---|---|---|

| Process Type | Batch operations | Automated systems | Continuous processes |

| Storage Space | Limited (dry storage) | Limited (dry storage) | Ample tank space |

| Dust Concerns | Moderate tolerance | Low dust required | No dust concerns |

| Dissolution Time | Can accommodate mixing | Prefer faster dissolution | Need immediate use |

| Handling | Manual/semi-automated | Fully automated | Pump systems available |

Three Optimized Forms of Caustic Soda

We supply sodium hydroxide in three specialized forms, each engineered for specific industrial requirements.

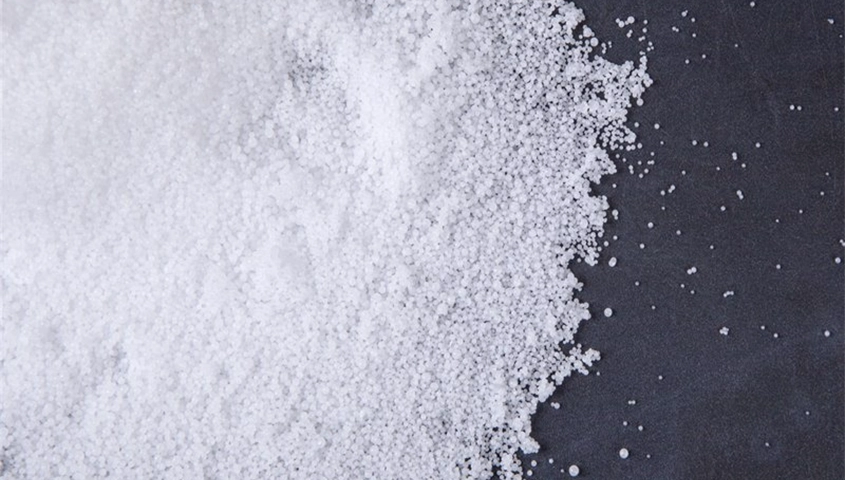

Caustic Soda Flakes (98-99% Purity)

White, crystalline solids are ideal for batch processes requiring rapid dissolution.

Technical Specifications:

-

Purity: 98-99% NaOH

-

Density: 2.13 g/cm³

-

Form: Irregular white flakes

-

Packaging: 25kg bags, 1000kg super sacks

-

UN Number: 1823

Best Applications:

-

Soap manufacturing (saponification)

-

Chemical synthesis in laboratories

-

Textile scouring (batch processing)

-

On-site effluent treatment preparation

Caustic Soda Pearls/Prills (99-99.5% Purity)

Spherical bead-like granules offering superior flowability and reduced dust generation.

Technical Specifications:

-

Purity: 99-99.5% NaOH

-

Size: 0.5-2mm diameter spheres

-

Dust Reduction: 40% less than flakes

-

Packaging: 25kg bags, 1000kg bulk bags

-

UN Number: 1823

Best Applications:

-

Automated dosing systems

-

Pharmaceutical API production

-

Food processing (peeling systems)

-

Polymer production catalyst

Liquid Caustic Soda (30-50% Solution)

Ready-to-use aqueous solution eliminating dissolution steps for continuous operations.

Technical Specifications:

-

Concentrations: 30%, 50% standard solutions

-

pH: 13-14

-

Density: 1.53 g/cm³ (50% solution)

-

Storage: Polyethylene or steel tanks

-

UN Number: 1824

Best Applications:

-

Municipal water treatment plants

-

Paper mill pulping operations

-

Petroleum refining desulfurization

-

Alumina refining (Bayer process)

Technical Comparison Table

| Property | Caustic Soda Flakes | Caustic Soda Pearls | Liquid Caustic Soda (50%) |

|---|---|---|---|

| Physical Form | Irregular white crystals | Spherical beads | Clear aqueous solution |

| Purity | 98-99% NaOH | 99-99.5% NaOH | 50% NaOH content |

| Density | 2.13 g/cm³ | 2.13 g/cm³ | 1.53 g/cm³ |

| Dust Level | Moderate | Low (40% less than flakes) | None |

| Dissolution Rate | Fast | Very fast | Instant (pre-dissolved) |

| Flowability | Good | Excellent | Pumpable |

| Primary Use Case | Batch processes | Automated systems | Continuous processes |

| Storage Requirements | Dry, sealed containers | Dry, sealed containers | Chemical-resistant tanks |

Application and Uses of Caustic Soda (Sodium Hydroxide)

Chemical Manufacturing

Caustic Soda is a fundamental raw material in the chemical industry and is used for:

-

Production of chlorine, sodium hypochlorite, and chlorinated solvents

-

Manufacturing of synthetic resins, plastics, dyes, pigments, and adhesives

-

Neutralization of acids and chemical reaction control

-

Production of surfactants and specialty chemicals

Pulp and Paper Industry

In the pulp and paper sector, Sodium Hydroxide plays a critical role in:

-

Pulp digestion (Kraft process) for separating lignin from cellulose fibers

-

Bleaching and de-inking of recycled paper

-

pH control during paper processing

-

Improvement of paper strength and quality

Water and Wastewater Treatment

Caustic Soda is extensively used for:

-

pH adjustment and alkalinity control

-

Neutralization of acidic water and industrial effluents

-

Removal of heavy metals through precipitation

-

Regeneration of ion exchange resins

-

Treatment of drinking water and municipal wastewater

Soap, Detergent, and Cleaning Products

One of the most common applications of Caustic Soda is in:

-

Saponification process for soap production

-

Manufacturing of liquid and solid detergents

-

Production of industrial and household cleaners

-

Degreasing agents and disinfectants

Oil & Gas Industry

In oil and gas operations, Sodium Hydroxide is used for:

-

pH control in drilling and completion fluids

-

Removal of acidic gases such as H₂S and CO₂

-

Refinery cleaning and equipment maintenance

-

Desulfurization processes

-

Neutralization of acidic petroleum streams

Textile Industry

Caustic Soda is essential in textile processing for:

-

Mercerization of cotton to improve strength, dye uptake, and luster

-

Scouring and bleaching of fabrics

-

Removal of natural fats, oils, and waxes

-

Dye fixation and finishing processes

Food and Beverage Industry

Food-grade Caustic Soda is used under controlled conditions for:

-

Cleaning and sanitizing food processing equipment (CIP systems)

-

Peeling of fruits and vegetables (chemical peeling)

-

Cocoa and chocolate processing

-

Olive curing and food pH regulation

(Used in compliance with food safety standards only)

Aluminum and Metal Processing

In metallurgical applications, Caustic Soda is used for:

-

Bayer process for alumina extraction from bauxite

-

Surface cleaning and degreasing of metals

-

Chemical polishing and etching of aluminum

-

Removal of oxide layers

Pharmaceuticals and Healthcare

Sodium Hydroxide is used in:

-

pH adjustment during pharmaceutical formulation

-

Synthesis of active pharmaceutical ingredients (APIs)

-

Cleaning and sterilization of production equipment

-

Laboratory and research applications

Agriculture and Fertilizer Industry

In agricultural applications, Caustic Soda is used for:

-

Production of herbicides, pesticides, and fungicides

-

pH regulation in agrochemical formulations

-

Cleaning and sterilization of agricultural equipment

-

Processing of animal feed ingredients

Mining and Mineral Processing

Caustic Soda is utilized in:

-

Ore processing and metal extraction

-

pH control in flotation processes

-

Neutralization of acidic mine drainage

-

Gold and base metal refining operations

Biodiesel and Renewable Energy

In renewable energy sectors, Sodium Hydroxide is used for:

-

Catalyst in biodiesel production

-

Transesterification of vegetable oils and animal fats

-

pH control in biofuel processing plants

Construction and Building Materials

Caustic Soda applications include:

-

Manufacturing of cement additives

-

Treatment of wood and building materials

-

Production of adhesives and sealants

-

Surface preparation and cleaning

Electronics and Semiconductor Industry

In high-purity grades, Caustic Soda is used for:

-

Etching of silicon wafers

-

Cleaning of electronic components

-

Surface treatment in semiconductor manufacturing

General Industrial Cleaning and Maintenance

Caustic Soda is widely applied for:

-

Industrial drain cleaning

-

Removal of grease, fats, and organic deposits

-

Heat exchanger and pipeline cleaning

-

Maintenance of industrial equipment

Grades & Specifications

We supply four specialized grades, available in all three physical forms.

| Grade | Purity | Key Standards | Primary Applications |

|---|---|---|---|

| Technical Grade | 95-98% | Industrial specifications | Soap, detergents, and general chemicals |

| Food Grade | ≥99% | FDA 21 CFR 184.1763, Halal, Kosher | Food processing, oil refining |

| Pharmaceutical Grade | >99.5% | USP/NF, EP, GMP | API synthesis, pharmaceuticals |

| Anhydrous Grade | 99.9% | ACS Reagent Grade | Batteries, semiconductors, fine chemicals |

Why Choose Our Caustic Soda Supply?

Quality & Compliance

-

High Purity: 98-99.5% NaOH ensures consistent reactions

-

Certifications: ISO 9001, ISO 14001, REACH registered

-

Traceability: Batch-specific Certificates of Analysis (CoA)

Supply Chain Advantages

-

Dual Sourcing: Production in Turkey + UAE warehouse stocking

-

Fast Delivery: 7-day delivery to MENA, Europe, and Africa

-

Strategic Locations: Warehouses in Istanbul, Mersin, and Jebel Ali

Commercial Benefits

-

Flexible Packaging: 25kg bags to bulk tankers

-

Competitive Pricing: Tiered rates starting at 20 MT

-

Technical Support: Free consultation from chemical engineers

Sustainability

-

Energy Efficient: 25% lower energy consumption via membrane cell technology

-

Responsible Production: Compliant environmental management

Safety Handling Guidelines

⚠️ Hazard Classification: Corrosive (Skin Corr. 1A, Eye Dam. 1)

Essential PPE Requirements:

-

Eyes: Chemical goggles + face shield

-

Hands: Butyl rubber or neoprene gloves (18 mil minimum)

-

Body: PVC apron and chemical-resistant coveralls

-

Respiratory: NIOSH-approved respirator for dust/vapor situations

Critical Safety Rules:

-

ALWAYS add caustic to water – NEVER reverse this order

-

Ensure adequate ventilation or use fume hoods

-

Store separately from acids in compatible containers (polyethylene)

-

Neutralize spills with weak acids (citric or acetic acid solutions)

First Aid Response:

-

Skin Contact: Remove contaminated clothing, flush with water for 20+ minutes

-

Eye Contact: Immediately flush with water for 20+ minutes, seek medical attention

-

Ingestion: Do NOT induce vomiting, rinse mouth with water, seek immediate medical help

[Download complete SDS sheets for all caustic soda forms]

Customer Testimonial

*”Their food-grade caustic soda pearls delivered 99.9% peeling efficiency in our olive processing line. The Dubai warehouse stock cut our lead time from 3 weeks to just 5 days, significantly improving our production scheduling.”*

– Production Manager, Olive Processing Plant, Oman

Technical Data Sheet of Caustic Soda Flakes

| CONTENT | TEST RESULT | UNIT |

|---|---|---|

| Al2O3 | Max 3 | PPM |

| Fe | 10 | PPM |

| Heavy Metals as Pb | Max 2 | PPM |

| Insoluble in Water | 0 | %W |

| Na2CO3 | 0.43 | %W |

| Na2SO4 | 0.0047 | %W |

| NaCl | 0.0085 | %W |

| NaOH | 98%±1 | %W |

| SiO2 | 0.0019 | %W |

| SHAPE | 0.3-1 | CM³ |

For Download Technical Data Sheets of Caustic Soda Flakes (Click Here)

Technical Data Sheet of Caustic Soda Pearls

| Property | Value | Unit |

|---|---|---|

| Melting Point: | 320-325 | ºC |

| Boiling Point: | 1385-1390 | ºC |

| Densityat20ºC: | 2.13 | g/cm3 |

| SolutionRate:(100g in 100ml water at25ºC): | 22 | s |

| Heat Capacity at 25ºC: | 2.01 | J/g.K |

| Heat of Fusion at 15ºC: | 167.5 | J/g |

| Standard Heat of Formation at 25ºC: | 10.67 | kJ/g |

| Specifications | ||

| Item | Value | Unit |

| Purity: | 99.0 Min | % |

| Sodium Carbonate (Na2CO3): | 0.8 Max | % |

| Sodium Chloride (NaCl): | 0.05 Max | % |

| Fe2O3: | 50 Max | PPM |

Technical Data Sheet of Caustic Soda Liquid

| No. | Specification | Unit | Acceptance Limit | Result | Test Method / Standard |

| 1 | Sodium Hydroxide (NaOH) Purity | % mass | Min 48 | 50 | ISIRI-6135 |

| 2 | Sodium Carbonate (Na₂CO₃) | % mass | Max 0.5 | 0.2 | ISIRI-6135 |

| 3 | Sodium Chloride (NaCl) | % mass | Max 0.03 | 0.01 | ISIRI-6135 |

| 4 | Sodium Sulfate (Na₂SO₄) | % mass | Max 0.007 | 0.001 | ISIRI-6135 |

| 5 | Silica (SiO₂) | % mass | Max 0.01 | 0.001 | ISIRI-6135 |

| 6 | Iron (Fe) | ppm | Max 10 | 3 | ISIRI-6135 |

| 7 | Aluminum Oxide (Al₂O₃) | ppm | Max 10 | <1 | ISIRI-6135 |

| 8 | Mercury (Hg) | ppm | Max 0.1 | 0.01 | ISIRI-6135 |

| 9 | Arsenic Oxide (As₂O₃) | ppm | Max 1 | <0.02 | ISIRI-6135 |